Understanding Digital Reliability

Manufacturing industries manage complex production environments where even a single hour of downtime caused by unreliable or unavailable assets can cost the manufacturer millions. Not to mention, there are added risks of hazardous leaks, life-endangering accidents, and a complete breakdown of the value chain. One of the reasons behind the uptake of Industry 4.0 technologies and systematic digital transformation is the need to overcome this inherent uncertainty in discreet and process plants.

Intelligent automation and advanced analytics can enable operation and maintenance teams to improve asset availability in their plants. Furthermore, mission-critical assets can be made more reliable, helping plant teams achieve intended targets and objectives. This is why there’s an increasing shift in focus toward digital plant reliability and manufacturing leaders are prioritizing the adoption of technologies that can drive these objectives.

This article will cover what digital reliability is, what are its benefits, and which technologies are driving digital reliability in manufacturing industries.

What is Digital Reliability?

Reliability is the probability of a system meeting certain pre-defined performance standards and delivering desired output for an intended period of time. A reliable system continues to perform within specific parameters, without experiencing any anomalies or breakdowns and operates at optimum productivity level. Digital reliability is ensuring asset and plant reliability through smart digitalization of processes and increased data availability to support decision-making.

Contemporary digital reliability solutions rely on real-time condition monitoring of manufacturing equipment, performing predictive analytics on collected data, and mapping the machine performance to generate a realistic health status of the asset. Data irregularities are investigated to diagnose existing or potential faults, and take corrective measures to mitigate the risk of failure.

Take a steel manufacturing plant, for instance, where a cold rolling mill is critical equipment that controls the production flow and throughput quality. The asset is responsible for achieving greater dimensional accuracy and increasing the hardness of the final product. If a cold rolling mill is available but not functioning under optimal conditions, then potential breakdown can lead to several hours of production downtime. With digital reliability measures, this eventuality can be avoided and the cold rolling mill can become highly reliable, saving over 72 hours of production downtime. (Read the full case here.)

Benefits of Digital Reliability

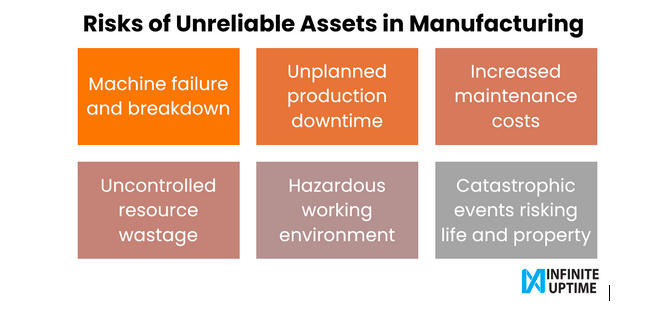

Digital reliability is becoming increasingly important in production environments as a lack of data-backed insights on machine health can diminish plant reliability, often resulting in:

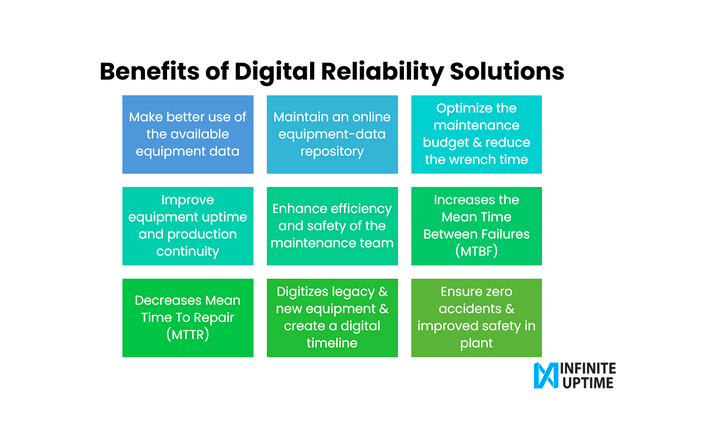

With responsively designed and implemented Digital Reliability solutions, these risks can be successfully mitigated. Plant maintenance and operation teams can intelligently put available equipment data to use and plan maintenance events to drive net productivity. The following benefits can be achieved with digital reliability in manufacturing setups:

Predictive Maintenance for Digital Reliability

More than 70% of equipment breakdown is due to mechanical faults, including equipment wear, deterioration, backlash, increase in clearances, vibrations, and acoustics. While for hydraulics, thermal and electrical faults, standard monitoring solutions are available, for mechanical faults, monitoring becomes challenging. To drive digital reliability objectives in these scenarios, predictive maintenance becomes an important enabler.

With Predictive Maintenance (PdM), plant maintenance teams can estimate the exact remaining useful life (RUL) of the equipment perform accurate diagnostics, and receive insightful recommendations to strategically plan maintenance activities. Real-time monitoring of triaxial vibrations, acoustics, and surface temperature is utilized to generate digital reliability reports and guide maintenance schedules. Responsive predictive maintenance solutions can also:

- Adapt to special production conditions

- Diagnose high-frequency data

- Accurately decipher the signal from noise

- Overcome complex bandwidth limitations

- Collect and store multi-location data on-cloud

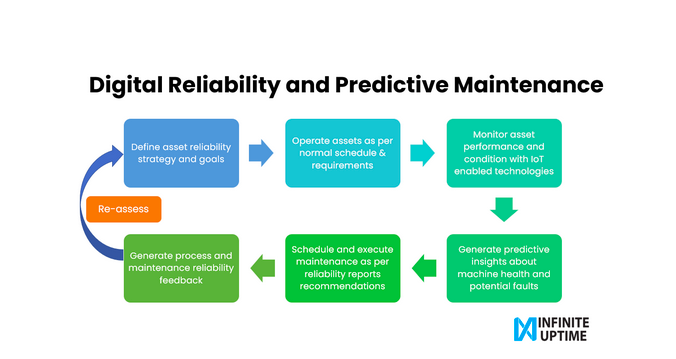

A predictive maintenance approach integrates naturally with the digital reliability objectives of any manufacturing setup. The monitoring objectives can be driven by digital reliability goals, and the final outcome of Predictive Maintenance activities can result in a feedback loop to refine and improve the digital reliability strategy.

Conclusion:

In sum, digital reliability ensures that all available assets in a production environment perform reliably as per pre-defined standards and metrics. With cloud-enabled predictive maintenance technologies, sophisticated digital reliability solutions can be tailored to suit the specific needs of a manufacturing unit. Continuous asset monitoring, and data-backed decision-making for the maintenance and operational activities, strategically drive digital reliability and create more productive and secure production environments.

Infinite Uptime offers responsively designed predictive maintenance solutions in diverse industries such as Cement, Steel, Mining and Metals, Tire, Paper, Automotive, Chemicals, FMCG, Oil and Gas, and more. To understand how predictive maintenance applies to your process plant and can help in driving digital reliability, explore the asset maintenance and reliability solutions of Infinite Uptime.