Understanding Asset Optimization in Manufacturing

Mission-critical assets in manufacturing setups can make or break an entire value chain. An unmitigated asset breakdown or productivity decline can halt production for hours, or even days, resulting in huge revenue losses and unsafe work environments. The situation becomes even more complex for industries with distributed assets.

To maintain assets in optimal condition and run the production process without disruptions, dedicated maintenance teams have to be deployed in various locations. Furthermore, investments are required in carrying spare-parts inventory and establishing strategic service contracts with Original Equipment Manufacturers (OEMs). While conventionally, these practices have been considered inevitable, a marked shift is happening towards predictive analytics and responsive maintenance solutions that can optimize asset performance.

This article will cover what exactly asset optimization is, why is it important for manufacturing industries, and how predictive maintenance solutions empower maintenance and operation teams to achieve it.

To maintain assets in optimal condition and run the production process without disruptions, dedicated maintenance teams have to be deployed in various locations. Furthermore, investments are required in carrying spare-parts inventory and establishing strategic service contracts with Original Equipment Manufacturers (OEMs). While conventionally, these practices have been considered inevitable, a marked shift is happening towards predictive analytics and responsive maintenance solutions that can optimize asset performance.

This article will cover what exactly asset optimization is, why is it important for manufacturing industries, and how predictive maintenance solutions empower maintenance and operation teams to achieve it.

What is Asset Optimization?

Optimization essentially means making something as effective, functional, reliable, and productive as possible. Asset optimization means optimizing the way that an asset is utilized and deriving maximum value from it. It also entails driving efficiency and reliability objectives by improving the Remaining Useful Life (RUL) of an asset and enhancing the Overall Equipment Effectiveness (OEE).

Asset Optimization depends on leveraging data-driven intelligence and predictive analytics to achieve business objectives and add to the bottom line. IoT-enabled technologies can be deployed to monitor asset conditions and analyze real-time data to determine maintenance needs.

Asset Optimization depends on leveraging data-driven intelligence and predictive analytics to achieve business objectives and add to the bottom line. IoT-enabled technologies can be deployed to monitor asset conditions and analyze real-time data to determine maintenance needs.

Benefits of Asset Optimization

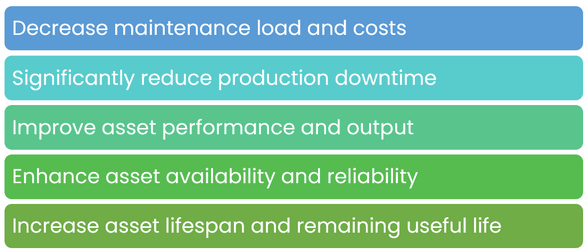

Optimal asset performance and availability have a dramatic effect on the overall productivity and throughput of a production plant. When assets are operating in optimal conditions, the following benefits are derived in discreet and process manufacturing industries:

In addition to these, safer and accident-free production environments can be created, with reduced risk of catastrophic events that could cost life and property. An indirect, yet palpable effect is also observed on revenue, margins, customer satisfaction, Return On Assets (ROA), and Work-In-Progress (WIP) inventory.

Challenges in Asset Optimization

Despite the incredible benefits that asset optimization offers, it is quite challenging to manage asset performance towards optimization. Major roadblocks in asset optimization are:

- Maintenance frequency: When manufacturing plants adopt breakdown maintenance (till failure) or scheduled (preventive) maintenance strategies, asset conditions often remain less than optimal. Either maintenance is performed when an asset breaks down or is performed periodically, irrespective of what the asset condition is. In both scenarios, it is impossible to extract the maximum use of an asset.

- Lack of data: Real-time information about asset conditions is rarely available, especially if manufacturing plants rely on offline asset inspections. Even when regular equipment inspections are performed manually, gaps remain in the data and many alarming signs about deteriorating equipment conditions may go unnoticed.

- Costly unplanned maintenance: For industries with distributed assets, unplanned maintenance in the event of machine breakdown proves to be very costly. A larger maintenance team needs to be maintained to cover the geographic distribution of assets. Spare parts and sub-assemblies need to be sourced at higher prices to fulfill urgent requirements. Not to mention, on-floor conditions are highly unsafe and hazardous for maintenance workers.

- Poor flow of information: Offline machine inspections and decentralized maintenance events create silos of information within the manufacturing organization. Critical information about asset conditions is not shared in real-time with all concerned stakeholders, and maintenance teams operate independently as per their capabilities.

- Ineffective utilization of resources: Both human and physical resources are utilized with limited visibility of the machine health and asset availability. Thus, maintenance activities are organized even when they are not needed and machine parts are replaced before their useful life is over.

Not only does it make the total cost of assets and maintenance higher, but it also creates a system acceptance of inefficient asset management practices. Planned downtimes become the norm and plant teams become resistant to change. Without a decided shift in the approach for asset performance management, asset optimization can be very difficult to achieve.

Asset Optimization through Predictive Maintenance

Predictive Maintenance solutions can help plant maintenance teams overcome the various challenges in asset performance management and ensure asset optimization across the plant. With a predictive approach, maintenance teams monitor asset conditions remotely with the help of cloud-enabled technologies. Vibration analysis, acoustics, thermography, oil analysis, and other remote condition monitoring techniques are deployed to track asset conditions while they operate as per schedule.

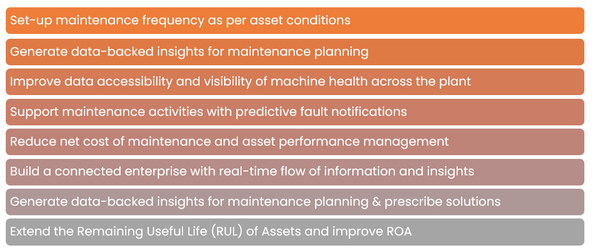

The machine health data is centrally collected and analyzed with the help of Industrial IoT (IIoT) technologies and accessible through responsive dashboards to concerned stakeholders. Since maintenance has to be strategized based on predictive insights, edge diagnostics, and advanced analytics are used to determine which asset is performing non-optimally and in need of attention. Such a focused approach to asset performance management has several benefits:

The machine health data is centrally collected and analyzed with the help of Industrial IoT (IIoT) technologies and accessible through responsive dashboards to concerned stakeholders. Since maintenance has to be strategized based on predictive insights, edge diagnostics, and advanced analytics are used to determine which asset is performing non-optimally and in need of attention. Such a focused approach to asset performance management has several benefits:

Conclusion

In sum, asset optimization ensures that all available assets are utilized optimally in a manufacturing environment. By tracking asset conditions in real-time and performing predictive analytics, maintenance activities can be scheduled to optimize asset performance. Improved flow of information within the manufacturing organization and data-backed planning of asset maintenance can improve net return on assets (ROA) and overall plant productivity.

Infinite Uptime offers responsively designed predictive maintenance solutions in diverse industries such as Cement, Steel, Mining and Metals, Tire, Paper, Automotive, Chemicals, FMCG, Oil and Gas, and more. To understand how predictive maintenance applies to your process plant and can help in optimizing asset performance, explore the plant reliability solutions of Infinite Uptime.

Infinite Uptime offers responsively designed predictive maintenance solutions in diverse industries such as Cement, Steel, Mining and Metals, Tire, Paper, Automotive, Chemicals, FMCG, Oil and Gas, and more. To understand how predictive maintenance applies to your process plant and can help in optimizing asset performance, explore the plant reliability solutions of Infinite Uptime.