Understanding Machine Diagnostics and Remote Monitoring

Managing machine health and ensuring sustainable asset performance is an important control objective in manufacturing environments. In both discreet and process-based manufacturing industries, net plant productivity, operational costs, and return on assets (ROA) depend on how well the available assets are utilized. This makes monitoring and diagnosing faults in all available assets a high priority for maintenance teams.

This article will cover what machine diagnostics are and how remote monitoring enables maintenance teams to track machine conditions, detect existing or impending faults, isolate the root cause, and initiate procedures to restore machine health.

What is Machine Diagnostic?

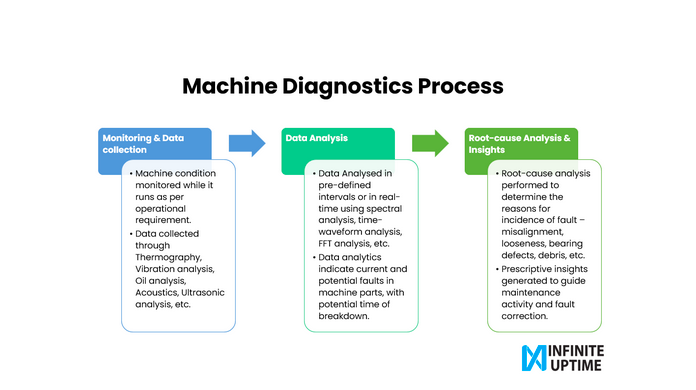

Machine diagnostics is an equipment control measure that focuses on tracking machine conditions and detecting faults that can lead to machine breakdown. The process includes fault detection, followed by root cause analysis. Machine diagnostics is critical in rotating machinery that operates round-the-clock and is essential for undisrupted production in a manufacturing environment.

Diagnostic data is collected with the help of various offline and online techniques, depending upon the scope of the maintenance. This data is then analyzed using methods like high-resolution spectral analysis, wavelet analysis or transform, Fast Fourier Transform (FFT), Wigner-Ville Distribution, waveform analysis, etc. The analyzed data is used to determine the root cause of faults and recommend corrective actions to the maintenance and operation teams.

For instance, a boom conveyor in a steel manufacturing plant can break down due to faults in motors, pulleys, or gearboxes. In a complex machine like this, it is difficult to determine what could have caused the breakdown and what kind of maintenance activity is required. With machine diagnostics, tri-axial vibration trends of the boom conveyor can be monitored to determine the root cause of machine breakdown.

If the machine’s health is deteriorating due to misalignment or bearing defects in the gearbox, then data-backed maintenance action can be carried out to restore machine function. (Read the full case here.)

What is Remote Monitoring?

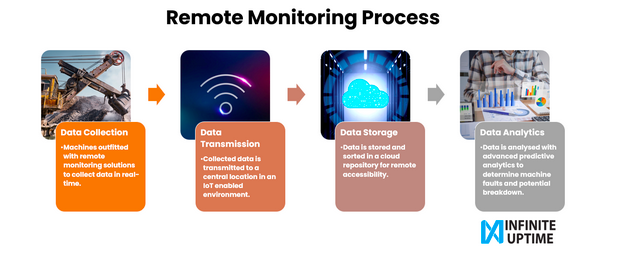

To make machine diagnostics efficient and empower maintenance teams with real-time data, machine health can’t be measured manually at sporadic intervals. There needs to be a system of continuous monitoring with complete data accessibility across the connected enterprise. This is achievable through remote monitoring of plant assets, using IoT-enabled technologies.

Remote monitoring deploys one or multiple cloud-enabled solutions to remotely monitor machine conditions. Machine vibration data is collected in real time and relayed via the cloud to a centralized repository. Any anomalies in the machine vibrations are analyzed and compared with pre-defined specifications to determine whether a fault exists or building up within the equipment. The maintenance teams can get complete visibility of machine health from any time, anywhere; facilitating a planned shift to the predictive maintenance approach.

Remote monitoring services also help create safer working conditions for maintenance and production teams. Potentially hazardous conditions can be detected from a safe distance, without any manual intervention on the site. At the same time, all maintenance-related decisions can be guided by data-backed insights, leaving very little to chance.

Remote Condition Monitoring for Machine Diagnostics

The most preferred method of remote monitoring is Condition Based Monitoring (CBM) in manufacturing industries. Condition monitoring is a non-destructive and non-disruptive technique of monitoring plant equipment to determine its health or condition at any point in time. Remote condition monitoring determines the stability or possible deterioration of equipment condition. The rate of deterioration and where exactly is the equipment in its life cycle are also determined and conveyed to concerned stakeholders.

Commonly used condition monitoring techniques in manufacturing industries are:

- Vibration Analysis: Measuring vibrations within a component, machinery, or machine group.

- Oil Analysis: Analysing oil contamination, and machine wear to determine asset health.

- Electrical Analysis: Analysing incoming power quality from the equipment, using motor current readings.

- Ultrasonic Analysis: Detecting high-frequency sound waves through ultrasonic analysis.

- Infrared Thermography: Detecting radiations and temperature changes using a thermal imager.

Of all these, vibration analysis is best suited for rotating equipment in process-based manufacturing environments. Abnormal machine vibrations are used to generate displacement, velocity, and acceleration maps, which in turn help in diagnosing the underlying causes of faults in the machine. Predictive analytical insights can be generated from this exercise which can support maintenance teams in planning focused repair and replacement events.

Conclusion:

In sum, machine diagnostics and remote monitoring are instrumental in managing asset performance and improving overall plant reliability. Real-time machine diagnostics using sophisticated, IoT-enabled techniques can give maintenance teams better visibility of asset conditions. With remote monitoring, machine diagnostics can be performed in a cost-efficient and secure manner, giving improved data accessibility across the organization. As machine faults are predictively diagnosed, corrective actions can be taken before the incidence of actual machine breakdown.

Infinite Uptime offers responsively designed machine diagnostics, remote condition monitoring, and predictive maintenance solutions in diverse industries such as Cement, Steel, Mining and Metals, Tire, Paper, Automotive, Chemicals, FMCG, Oil and Gas, and more. To understand how predictive maintenance applies to your process plant and can help in achieving plant reliability, explore the comprehensive solutions of Infinite Uptime.