Predictive Maintenance as a Service for Cement Industry: An Overview

The cement manufacturing industry is one of the oldest and most critical manufacturing industries for the global civilization. It has witnessed unparalleled growth at the heart of most economic developments and international growth this decade. Fortune Insights report says, the global cement market will grow from $326.80 billion in 2021 to $458.64 billion in 2028, a steep 5.1% globally. It is then no wonder that cement plants face pressure for process and asset maintenance.

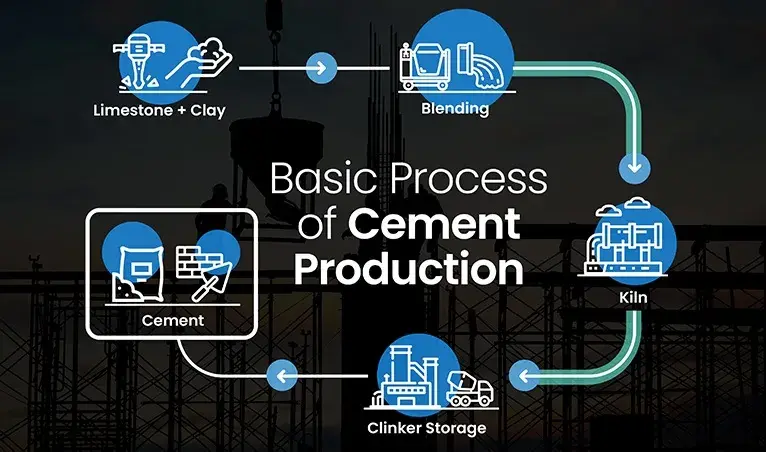

CEMENT MANUFACTURING PROCESS & NEED FOR PREDICTIVE MAINTENANCE

Cement manufacturing is one of the most complex continuous manufacturing processes, with multiple ingredients & steps involved. Here is an overview of the entire process wrt machines used at each stage:

Predictive Maintenance checklist for cement industry:

- Extractors: Used to Quarry the raw materials, i.e. limestone & clay

- Crushers used to crush high rock piles into coarse powders called raw meal

- Blenders & Mixers mix the crushed raw meal in the right proportions

- Grinders to further grind the raw material to free different minerals in the ore

- A rotary kiln where the raw meal is heated up to 1450 degrees & then cooled

- Assembly belts & conveyors to carry the cement for packing & dispatching to customers

Common causes for machine downtime in a cement plant

- Loose nuts, bolts, springs, plates, spring rods, flywheel, bearings, shaft, coupling housing, hammer rotor

- Motor failure, Conveyor belt, breakage, bearing failure, stretching rod breakage, breakage of separator blade

- Fan bearing breakage, fan unbalance

- Gear knocking, gear tooth wear, gear deformation, gear spitting and spalling

- Axle spindle breakage, crusher bearings failure, slip tape breakage

- Disc liner shift

- Rolling mill cracks, tubing failure, pump failure, spoke breakage

- Grate plate breakage

Why asset maintenance in cement plants is a necessity?

Asset maintenance in cement plants is critical because:

- Extensive repair & replacement costs

- Chances of industrial safety hazards & accidents

- Over maintenance of equipment, causes wear & tear

- Harsh operating environment

- Dynamic environment, needing proactive decision making

- Enable remote monitoring & control for agility & resilience to

How can Predictive Maintenance as a Service help?

With the stakes so high and a constantly changing environment, real-time machine diagnostics are necessary to empower plant managers with the correct data. IIoT can enable this by enabling a 360-degree view of interconnected assets across the plant. Predictive maintenance as a service allows plant managers in cement managers to move away from reactive measures like reactive maintenance and preventive maintenance to a predictive one, where critical machines don’t have to be pulled down unless there is a specific anomaly.

At a grass root level, predictive maintenance as a service by IU for cement plants can be implemented by putting sensors at strategic positions on the machines. Vibration analysis of mechanical equipment components like Air Compressors, Belt drives or Conveyors, Fans and blowers, Kiln rollers, Motor bearings & Vertical and horizontal mills can help predict anomalies.

The Predictive Maintenance as a service solution by Infinite Uptime involves collecting data, analysis & computing of the triaxial vibrations, temperature and noise of the mechanical equipment on edge at real-time via a patented edge computing system. The data then is monitored & analyzed in real-time, and a machine health score is assigned. A machine with a lower health score is flagged to the plant supervisor or plant engineer with a diagnostic assessment of the probable cause for the anomaly and a recommendation on improving the same. Not just that, if not considered severe yet, but still significant; the fault is continuously monitored, with relevant parameters like temperature, vibration etc., to assure that it does not aggravate the status quo. This information can be made available in real-time to the appropriate people at their fingertips. An access-based dashboard ensures that you get access to the most relevant machine data for the plant from single machine access for a plant operator to multiple machines across the plant access for a plant head and a multi-plant machine score for a manufacturing head. Let’s look at a case study around how we helped a top Indian cement manufacturer reduce 250 hours of downtime.

Conclusion

Today, the cement industry is on the cusp of digital transformation, fueled by rising demand and cut-throat competition and increasingly stringent regulations. The pressure on the cement industry’s assets, processes, and people to be on the top of their game has never been higher. In such a scenario, Predictive Maintenance as a Service for your cement plant can help avoid machine failures and the associated unplanned downtime and the quality of the output cement and the OEE (Overall Equipment Effectiveness) of the cement plants. It improves machine availability and performance, also saving costs for repairs & spare parts. But most importantly, it arms you with resilience & agility during unpredictable times via remote monitoring and proactive maintenance when needed the most.