Case Study

Advanced Fault Diagnosis For Cement Mill Gearbox

1. Abstract

Clinkers, a mix of limestone, additives and iron dust are produced in a Cement Kiln in

the form of nodules 3 mm to 25 mm in diameter. A cement mill grinds the hard, nodular

clinker from the cement kiln into the fine grey powder that is cement. It is the last core

equipment in the cement making process. This paper demonstrates the use of Infinite

Uptime’s auto-diagnostics features to help detect faults for complex gear train

assembly used to drive the cement mill.

2. Introduction

The Cement Mill indicated in the Figure 1(schematic) is installed at a 112 TPH

capacity cement plant and the mill drive is supplied by Flender. Sensors for prediction

of fault diagnosis are mounted at the marked positions in motor and gearbox. (See Figure 1). These sensor nodes communicate to a cloud dashboard and provided

comprehensive vibration signal analysis and fault diagnosis.

3. Background

3.1 Cement Ball Mill Construction

The Cement ball mill contains a hollow cylinder (filled with stainless steel or rubber balls) shell that rotates about its axis for grinding the material to fine form. Ball Mill uses drives which are required to have high reliability and efficiency over a long period in harsh environments. The final torque from the main gearbox is transferred to a

pinion and girth gear drive through a cardan shaft. Running such an equipment under a fault condition could quickly damage drive components and could be fatal.

3.2 Sequence of Events

Figure 2 shows the sequence of events in a summarized way.

Figure 2: Sequence of Events

4. Solution

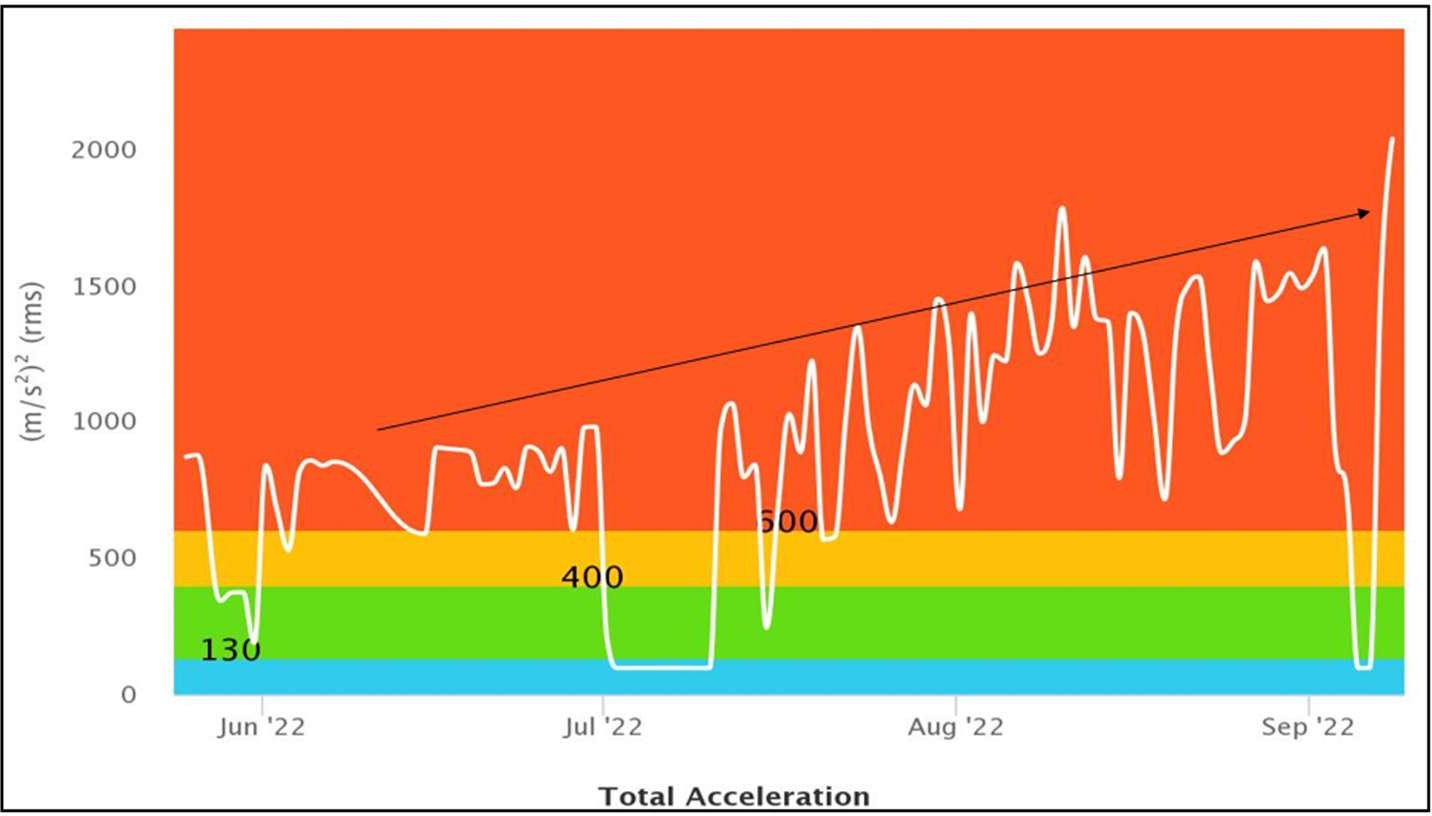

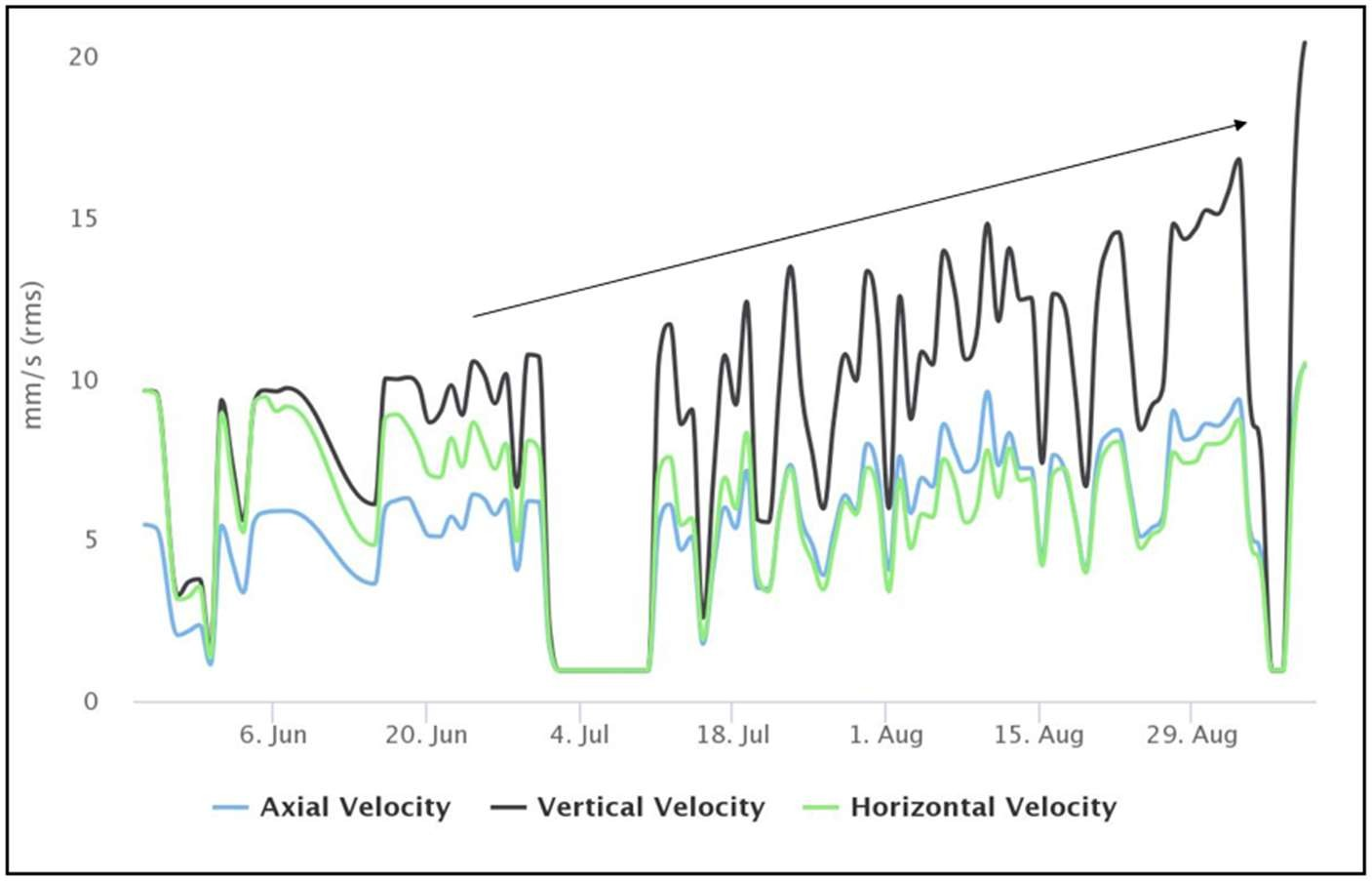

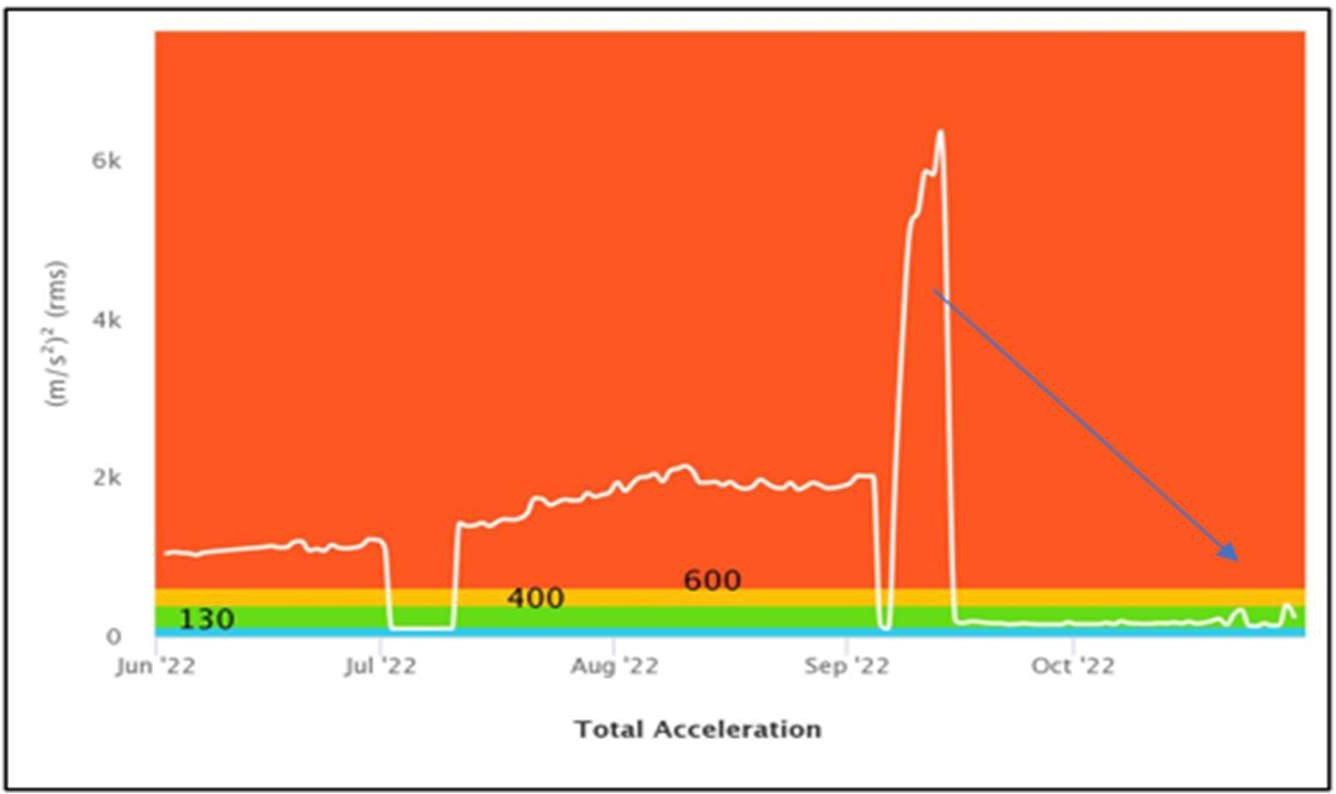

Using advanced fault diagnostic trend charts of key parameters resulted in fault detection.Figure 3, Figure

4, and Figure 5 show the increase in trends and rise in spectrums on the respective

dates. Figure 6 shows the reduction in Total acceleration after maintenance

4.1 Advanced Fault Diagnosis in IDAP Platform

3. Dominating 1xGMF & its harmonics with 1x GBX I/P RPM sidebands are observed. In time waveform periodic impacts at 1xGBX I/P RPM spacing are observed.

Previous

Next

Figure 5: Girth & Pinion Gear Mesh Frequencies

4.2 Site Inspection and Findings

Site team inspected the gearbox and found broken gear teeth as shown in below figure.

It can be seen in figure 7 that the crack originated at the root fillet on the tensile side of the tooth and slowly progressed to complete the fracture along the tooth. The face of the fracture is characterized by contour lines or “beach marks”. Repeated bending stress above the endurance limit of the material resulting from an alignment problem seems to have caused the failure. To avoid localized gear tooth loading, gear alignment and gear face modifications must be examined.

It can be seen in figure 7 that the crack originated at the root fillet on the tensile side of the tooth and slowly progressed to complete the fracture along the tooth. The face of the fracture is characterized by contour lines or “beach marks”. Repeated bending stress above the endurance limit of the material resulting from an alignment problem seems to have caused the failure. To avoid localized gear tooth loading, gear alignment and gear face modifications must be examined.

5. Conclusion

Shockwave spectrum and total acceleration are critical parameters which can be used to identify defects in gears like misalignment, improper meshing and gear teeth damage. Auto diagnostics features using these parameters were able to accurately predict the faults in gearbox well in advance in cement ball mill avoiding an estimated 12 hours of production loss.