Why 95% of GenAI Projects Failed and How Prescriptive AI and the 99% Trust Loop Are Changing Manufacturing

Key Takeaways

02

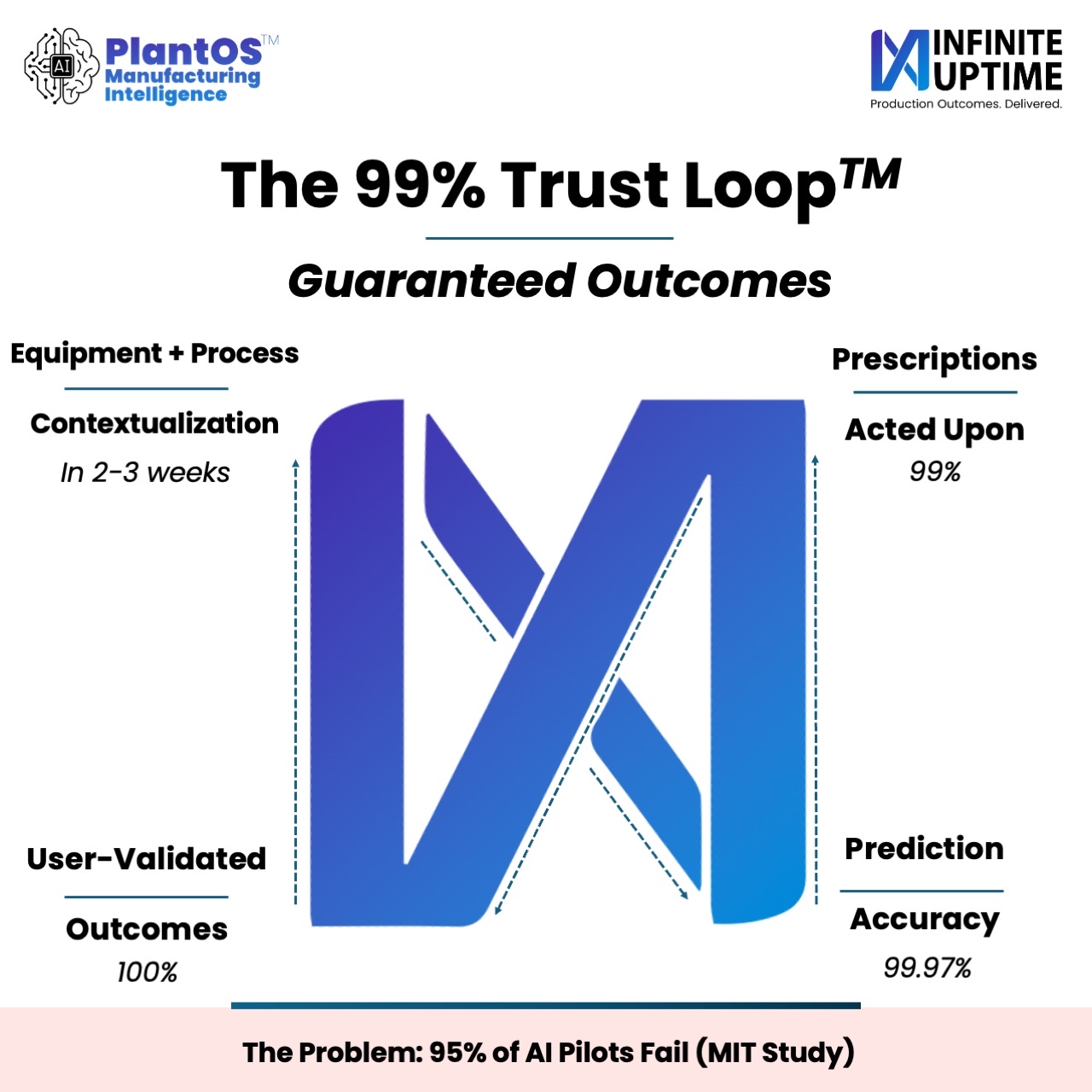

PlantOS™ creates the 99% Trust Loop that delivers user-validated outcomes with 99.97% prediction accuracy and 99% prescriptions acted on.

03

The shift from dashboards to prescriptive AI helps teams move from data visibility to confident, action-driven decision-making.

05

Plants using PlantOS™ achieve up to 40X ROI,

115,704 validated hours of downtime avoided, and measurable improvements in throughput and energy efficiency.

In 2025, MIT reported a stunning figure: 95% of GenAI projects failed to reach real production environments. Despite major investment, most systems never moved beyond pilots or proofs of concept. The issue was not lack of potential. The issue was lack of action.

GenAI generated insights, summaries, and predictions. But on the shop floor, what manufacturers needed was decisions.

Heavy industry operates in a world where every minute of downtime carries financial and safety implications. Dashboards and suggestions are helpful, but they rarely provide the clarity required to make confident operational decisions. Teams need to know what to do right now, why it matters, and what outcome it will produce.

This is where the industry is shifting. Not toward more predictive or generative systems, but toward prescriptive AI. And not toward assumed outcomes, but toward operator-validated truth.

The Move to Prescriptive, Action-Driven AI

Prescriptive AI goes beyond forecasting. It recommends a specific action and explains the reasoning behind it.

For industrial operators, this distinction is critical. The value lies not in the prediction itself but in the moment a technician decides whether to stop a machine, adjust equipment, or replace a component. GenAI could not bridge that gap. Prescriptive AI does, because it is designed to support human decision makers, not replace them.

The Rise of Operator-Validated Outcomes

After years of experimenting with siloed pilots, one lesson has become clear: AI only works when operators trust it.

- Prediction: High-accuracy detection of early signals

- Prescription: Clear recommendations detailing what to do, why, and when

- Action: Operators perform the task with contextual guidance

- Outcome Validation: The operator confirms the result, proving what worked

This final stage, often ignored in traditional systems, is where trust is built and where AI shifts from insight generator to reliability partner.

The Data Behind The 99% Trust Loop

- Up to 40X ROI in production environments

- 99.97 percent prediction accuracy

- 99% prescriptions acted on

- 28,551 operator-validated outcomes

- 115,704 hours of downtime saved

- Deployment across 844 plants worldwide

These are not theoretical results. They are validated by frontline teams, one outcome at a time.

Why This Matters for U.S. Manufacturing

To succeed in this environment, AI must be explainable, reliable, fast to validate, trusted by operators, and tied directly to financial outcomes. Prescriptive AI meets those requirements. GenAI does not.

The 99% Trust Loop, grounded in operator verification, is designed for the realities of steel mills, cement kilns, tire plants, and large-scale production environments where every decision carries weight.

From Pilot Paralysis to Verified Outcomes

If 2025 marked the collapse of GenAI hype cycles in manufacturing, 2026 marks the rise of reliability-driven AI. A move from experimentation to execution. From dashboards to decisions. From insight to action. From prediction to proof.

That is what the 99% Trust Loop is built to deliver.

Close the Trust Loop in Your Plant.

Join 841 plants using PlantOS™ to achieve up to

40× ROI through prescriptive, validated outcomes.