Predictive Maintenance: A Comprehensive Guide 2025

Table of Contents

- Introduction

- What is Predictive Maintenance?

- History of Predictive Maintenance

- Key Components of Predictive Maintenance

- Predictive Maintenance Technologies

- Types of Predictive Maintenance

- Advantages of Predictive Maintenance

- The Impact of Predictive Maintenance

- Predictive Maintenance Challenges

- Predictive Maintenance Example

- Industry Use Cases of Predictive Maintenance

- Future of Predictive Maintenance

- Conclusion

What is Predictive Maintenance?

History of Predictive Maintenance(PdM)

What does pdm stand for in maintenance ?

PdM in maintenance stands for Predictive Maintenance. It refers to a maintenance approach that uses real-time and historical equipment data to predict when a machine or component is likely to fail. By monitoring indicators such as vibration, temperature, pressure, and energy consumption, PdM helps maintenance teams identify early signs of degradation and schedule interventions before a breakdown occurs. The goal of PdM is to reduce unplanned downtime, avoid unnecessary maintenance, and extend equipment life by acting at the right time based on actual asset condition.

Key Components of Predictive Maintenance

Predictive maintenance is an advanced approach to maintenance that leverages technology and data to foresee potential equipment failures before they occur. By integrating various components, organizations can enhance the reliability and efficiency of their operations. Understanding these key components is crucial for implementing a successful predictive maintenance strategy. Here are the essential elements that make predictive maintenance effective:

Predictive Maintenance Technologies

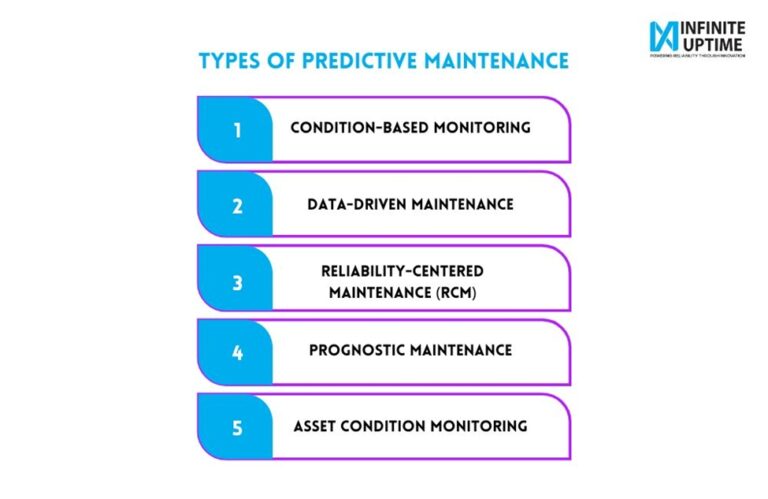

Types of Predictive Maintenance

Advantages of Predictive Maintenance

The Impact of Predictive Maintenance

Predictive Maintenance Challenges

Predictive Maintenance Example

Example: Cement Plant Kiln Drive System

Industry Use Cases of Predictive Maintenance

Future of Predictive Maintenance

Role of AI in predictive maintenance

Artificial Intelligence (AI) plays a critical role in predictive maintenance by analyzing large volumes of real-time and historical equipment data—such as vibration, temperature, pressure, current, and acoustics—to detect early signs of asset degradation. Unlike traditional rule-based monitoring, AI learns the normal operating behavior of machines and identifies subtle anomalies that indicate potential failures before they occur.

Beyond prediction, AI-driven prescriptive maintenance provides clear, actionable guidance by diagnosing root causes and recommending what action to take, when to take it, and the impact of delaying it. These insights help maintenance teams plan work during scheduled shutdowns rather than reacting to emergencies, while avoiding unnecessary maintenance. For industrial operations, this leads to reduced unplanned downtime, lower maintenance and spare-part costs, extended equipment life, improved safety, and more consistent, efficient plant performance.

Conclusion

Infinite Uptime delivers cutting-edge machine diagnostics, remote condition monitoring, and predictive maintenance solutions across a range of industries, including Cement, Steel, Mining, Metals, Tire, Paper, Automotive, Chemicals, FMCG, Oil and Gas, and beyond. Discover how our innovative predictive maintenance technologies can enhance reliability and performance in your process plant. Explore the tailored solutions provided by Infinite Uptime to see how they can support your operational goals. We are available in the USA, India, and EMEA to serve your needs globally.

Read More on Prescriptive Maintenance

What Is Prescriptive Maintenance and Why It’s the Future of Industrial Reliability?

As industries continue to evolve with digital transformation, traditional maintenance...

Condition-Based Maintenance vs. Prescriptive Maintenance: Key Differences Explained

As industrial operations become more complex and cost pressures increase,...

Prescriptive vs Predictive Maintenance

Prescriptive vs predictive maintenance refers to two different industrial maintenance...