Industries & Outcomes

“ Infinite Uptime has been a strategic partner of JSW for the last four years,

playing a pivotal role in transforming & optimizing our Steel, Cement and Paint Plant production outputs.”

– Rishi Shroff, CEO, JSW New Age

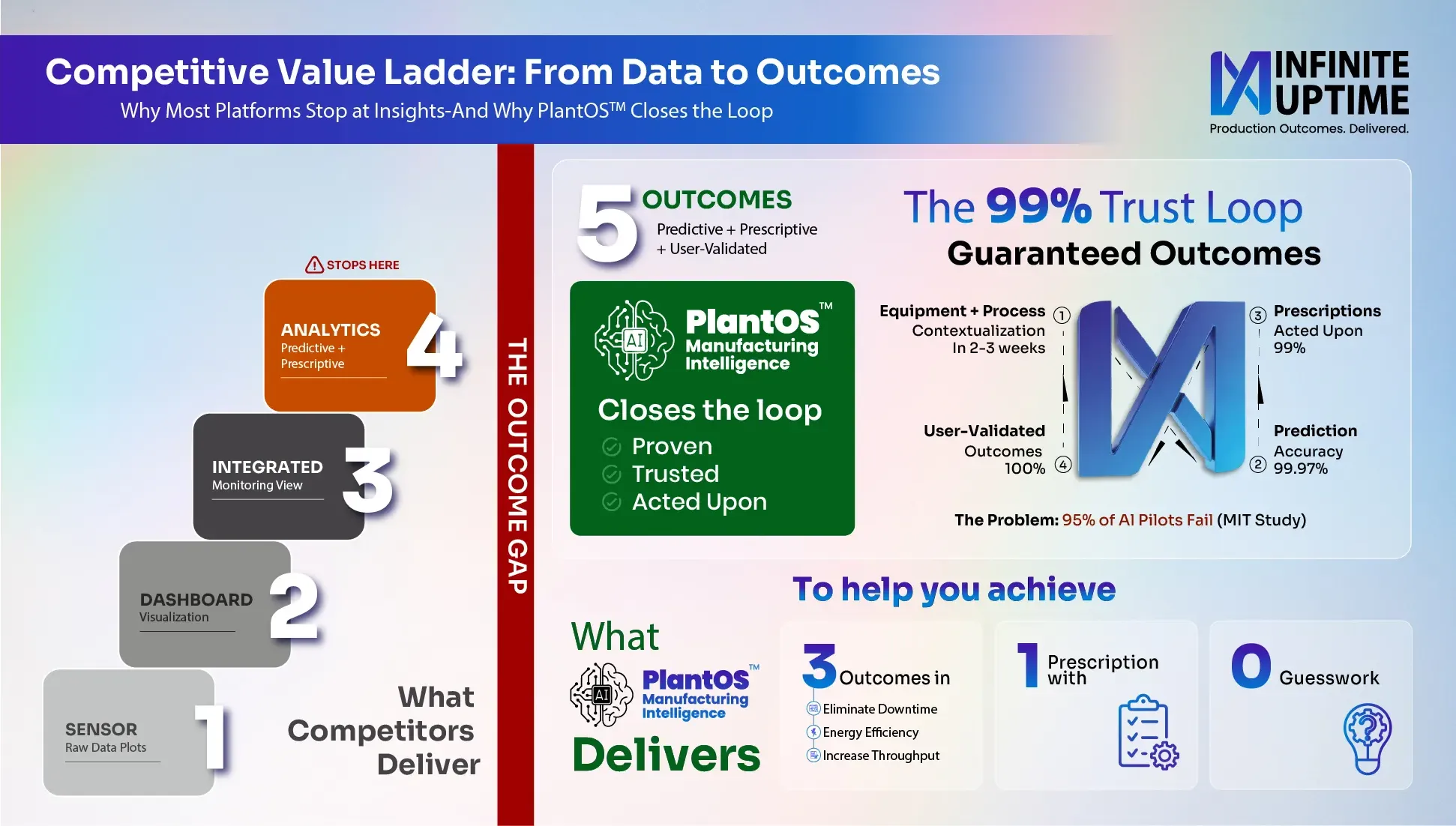

Infinite Uptime’s PlantOS™

Prescriptive Maintenance &

Energy Efficiency Powered by PlantOS™

dual advantage for process industries.

Through Prescriptive Maintenance, it not only predicts potential failures but also recommends the right action at the right time to keep critical equipment running reliably

At the same time, Energy Efficiency is embedded into every insight, detecting process inefficiencies, optimizing equipment loads, and reducing energy consumed per tonne of output.

PlantOS™ covers entire production ecosystems to achieve higher uptime, lower maintenance &

energy costs, safeguard ROI, and drive safety for all employees.

Strategic Challenges

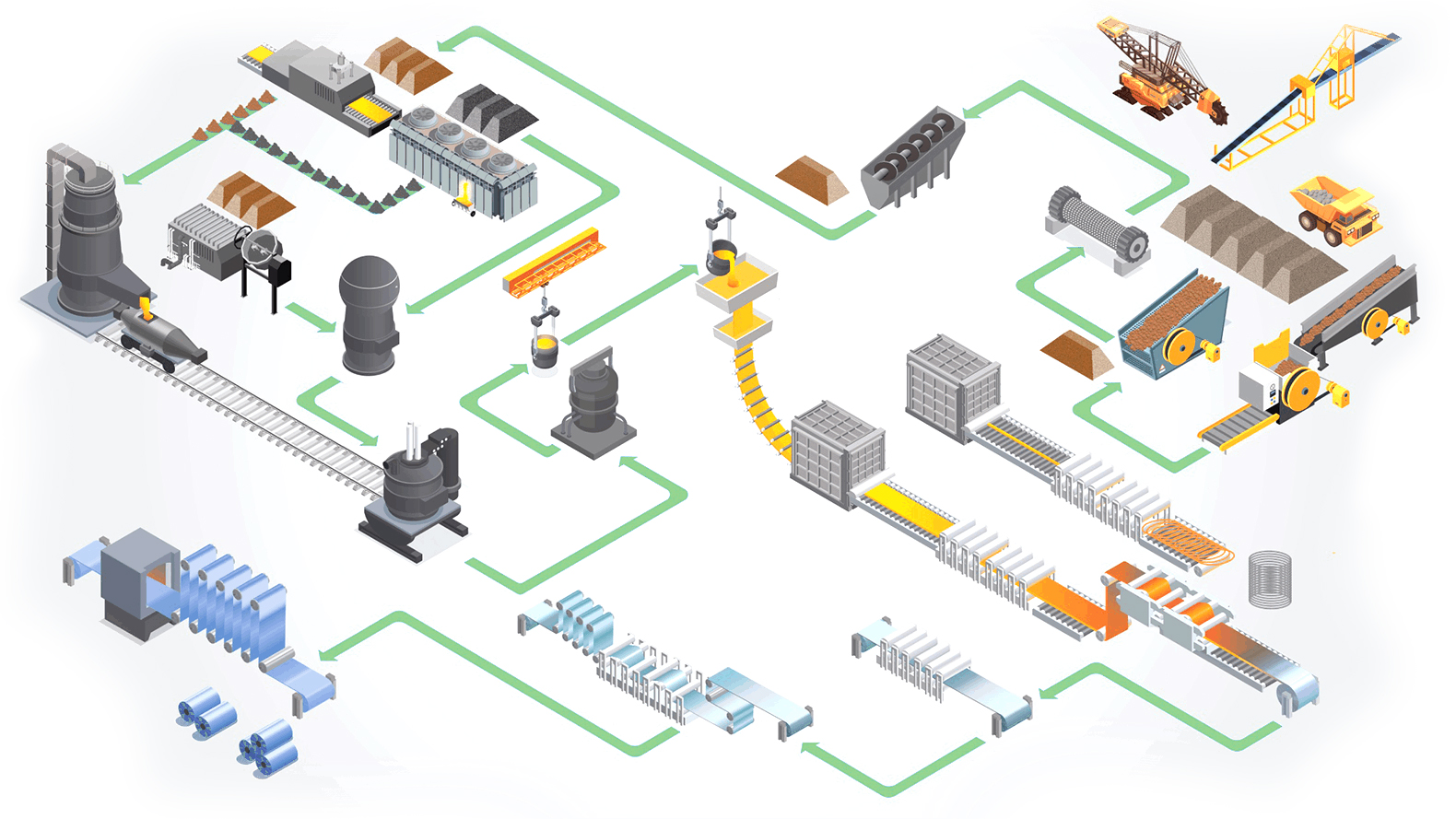

Production Reliability for

Steel Industry

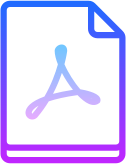

Mining

Grizzly Feeder

Jaw Crusher

Vibration Screen

Ball Mill

Stacker Reclaimer

Cyclone Separator

Conveyor

Coke Oven

Hammer Mill

Exhaust Blower

Dedusting Fan

Cooling Water Pump

BOD Blower

Vapor Compressor

Sinter Plant

Pallet Car

Mixing Drum

Sinter Crusher

Sinter Screen

Cooller Fan

Exhaust Blower

Dedusting Fan

Conveyor

Blast Furnace

Dedusting ID Fan

Stock House Conveyor

Sinter Fines Fan

Booster Fan

VPSA Blower

VPSA Pump

BLT Charging Unit

Steel Melting Shop (SMS)

Converter Saturated Pump

Converter GCP Pump

Dedusting ID Fan

Caster Mould Pump

Caster Booster Pump

Caster Slide Gate Pump

Caster Steam Fan

Scale Pit Pump

GAC Pump

Pellet Plant

Exhaust Fan

UDD Fan

Recuperator Fan

Ball Mill

Tailing Pump

Bucket Elevator

Conveyor

Pelletizing Disc

Corex

Top Dedusting Fan

Coal Dedusting Fan

Ore Dedusting Fan

Ore Conveyor

Hot Strip Mill

Mill Stand

Mill Drive

Pinch Roll

Cradle Roll

Mill Drive

Cooling Tower

Fume Exhaust Fan

Furnace Blower

Wire Rod Mill

Mill Stand

Looper

Pinch Roll

Circulation Blower

Tandem Cold Rolling Mill

Mill Stand

Mill Drive

Uncoiler

Recolier

Tension Reel

Delivery Looper

Fume Exhaust

Continuous Galvanizing Line

Bridle Roll

Fume Exhaust Blower

Air Knife Blower

Coater Passivation Blower

Coating Line

Uncoiler

Recolier

FD Fan

Fume Exhaust

Bridle Roll

Round-the-clock operations, extreme furnace conditions, massive energy demand, and abrasive environments

make unplanned stoppages both frequent and expensive. A single failure in a blast furnace blower, rolling mill drive,

or cooling system can halt production and drive energy costs through the roof.

Outcomes Delivered

JSW Steel Transformation Success Story

Hours Eliminated

The PlantOS™ Difference

PlantOS™ goes beyond Condition monitoring by prescribing timely interventions for all critical equipment such as:

Strategic Challenges

Production Reliability for

Cement Industry

Every kiln stoppage risks millions, every ton risks ESG penalties

Raw Material Handling

Stacker Reclaimer

Crusher

Feeder

Vibrating Screen

Belt Conveyor

Raw Mill Section

Vertical Roller Mill

Classifier

Raw Mill Fan

Belt Conveyor

Raw Mill Exhaust Fan

Pyro Section

Kiln Main Drive

Girth Gear & Pinion

PA Fan

Preheater Fan

Bag Filter Fan

Kiln Feed Elevator

Clinker Cooler Fan

Silo

Deep Pan Conveyor

Belt Conveyor

Cement Mill

Mill Main Drive

Bucket Elevator

FD Fan

ID Fan

Roller Press

Planetary Drive

Movable Roller

Fixed Roller

Packaging Plant

Bucket Elavator

Deep Pan Conveyor

Bag Filter Fan

Powerplant Boiler Feed Pump PA Fan SA Fan ID Fan CEP Pump Vacuum Pump Cooling Water Pump Demineralization Pump Gas Turbine Cooling Tower Fan

mills, fans, and filters. A single stoppage can choke operations, shorten

equipment life, and send power consumption soaring.

Outcomes Delivered

Cement Transformation Success Story

Hours Eliminated

The PlantOS™ Difference

Strategic Challenges

Production Reliability for

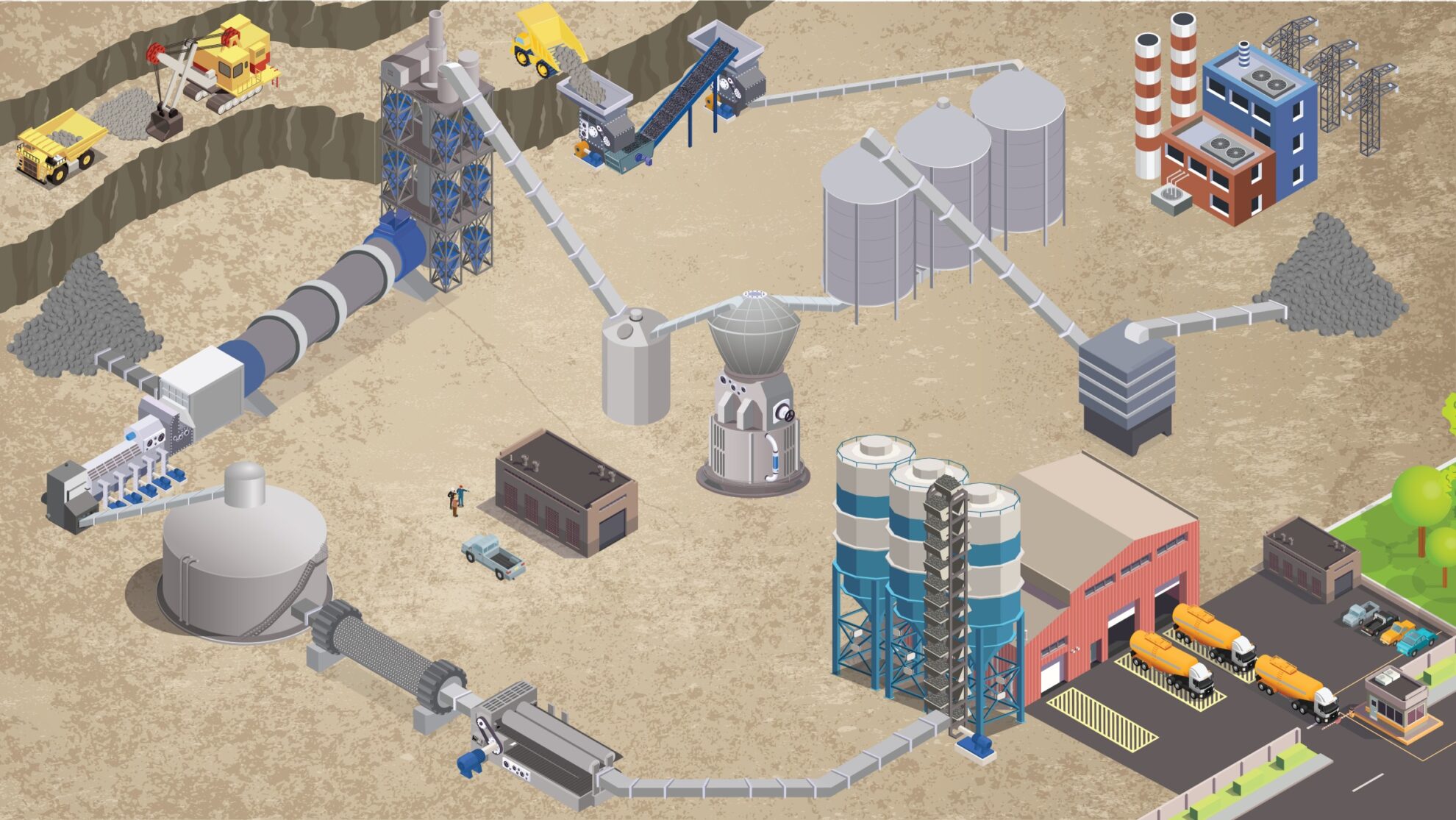

Metals & Mining Industry

Prescriptive Maintenance & Energy Optimization with Proven ROI in 6–12 Months

Green Anode Plant (GAP)

Ball Mill

Bucket Elevator

ID Fan

Kneader

Paste Mixer

Baking Furnace

FTA Blower

FTA Compressor

FTP ID Fan

Rodding

Autogenous Mill

Belt Conveyor

Shot Blast Unit

Dust Collector Fan

Butt Press Pump

Potline

Circulation Blower

ID Fan

Belt Conveyor

Cast House

Ingot Transfer Fork

Cooling Conveyor

Layer Conveyor

Stack Conveyor

Casting conveyor

Wire Rod Mill

Cooling Tower

Saw Cutter

Air Compressor

Pit Pump

Crane

Billet Cutter

Rolling

Rough Rolling Stand

Finish Rolling Stand

Annealing

Cooler Fan

Power plant Boiler Feed Pump PA Fan SA Fan ID Fan CEP Pump Vacuum Pump Cooling Water Pump Demineralization Pump Gas Turbine Cooling Tower Fan

Outcomes Delivered

Mining & Metals Transformation Success Story

Hours Eliminated

The PlantOS™ Difference

Mining

Metals

Strategic Challenges

Production Reliability for

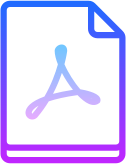

Pulp & Paper Industry

mill hour downtime can cost up to $150,000

Prescriptive Maintenance & Energy Optimization with Proven ROI in 6–12 Months

Pulping

Digester

Mixer

Reactor pump

Tower feed pump

Press Feed Pump

Pulp Press Roll

Disc Filter

Twin Roll press

Vacuum Drum Washer

Evaporator

Chemical Recovery

Weak Chlorine Blower

Chlorine Supply Pump

Air Compressor

Caustic Pump

Recovery Boiler Pump

ID Fan

Scrubber Unit

Slaker

Washer

Refiner

Bleacher

Forming

Breast Rolll

Table Roll

Dandy Roll

Couch Roll

Wire Roll

Drying Drying Cylinder Felt Roll Vaccum Roll Yankee Cylinder

Calendaring Top Roll Intermediate Roll Queen Roll Deflection Roll Compensating Roll

Reeling Reel Drum Roll Reel Spool Roll Rider Roll Winder Drum Roll

Water Treatment Plant Raw Water Pump Dosing Pump Return Sludge Pump Air Compressor

Powerplant Boiler Feed Pump PA Fan SA Fan ID Fan CEP Pump Vacuum Pump Cooling Water Pump Demineralization Pump Gas Turbine Cooling Tower Fan

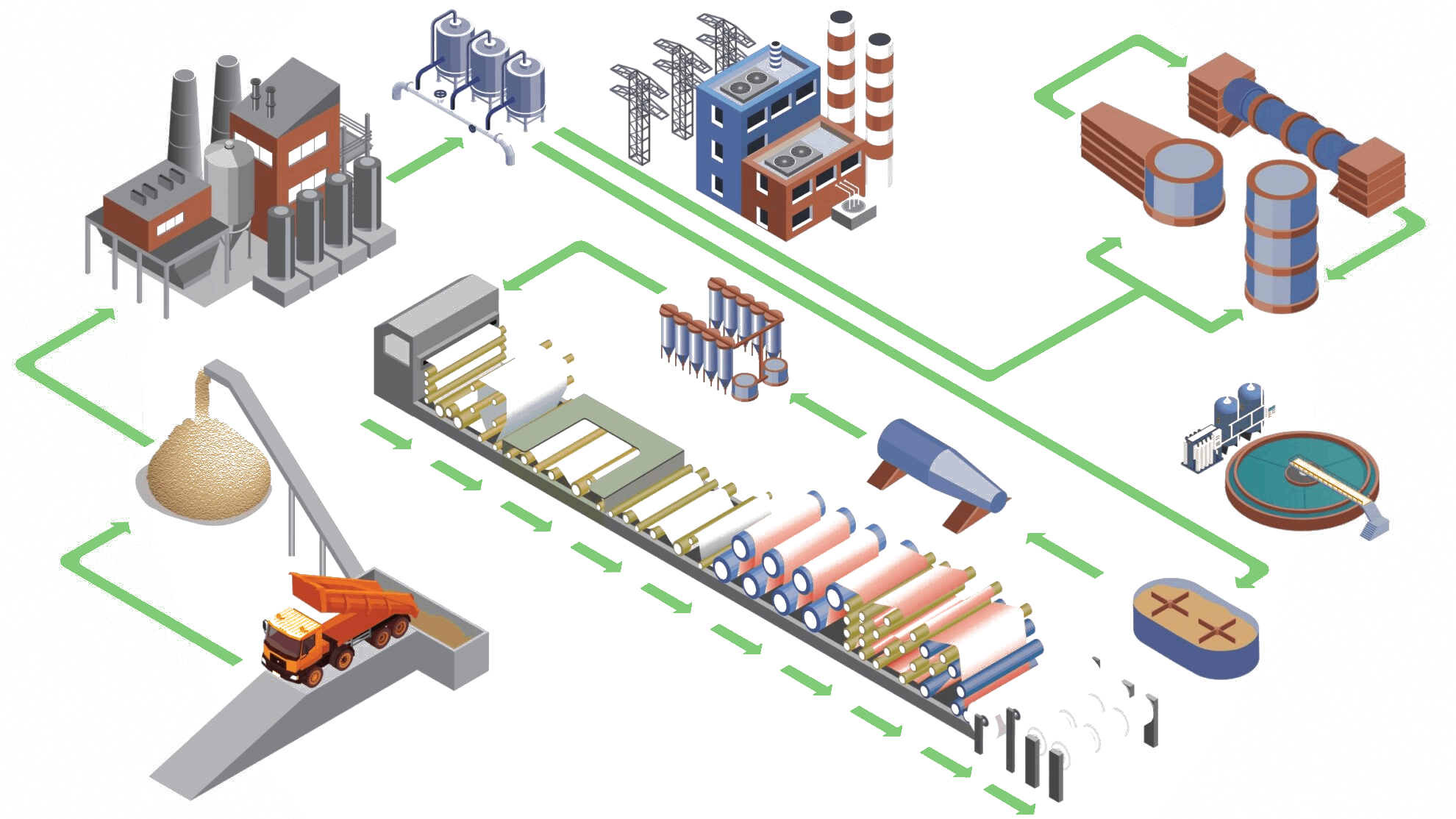

Unplanned stoppages cause costly paper breaks, wasted raw material, excessive

steam consumption, and lost output — while maintenance in such harsh

environments is both frequent and expensive.

Outcomes Delivered

Hours Eliminated

The PlantOS™ Difference

It recommends the right fixes before breakdowns occur and pinpoints

energy optimization opportunities across the process.

Strategic Challenges

Production Reliability for

Chemicals & Fertilizers Industry

Chemicals = safety-critical, compliance-driven, cost-intensive

A single reactor failure risks millions — and regulatory shutdowns

Prescriptive Maintenance & Energy Optimization with Proven ROI in 6–12 Months

Outcomes Delivered

Hours Eliminated

The PlantOS™ Difference

(Centrifugal/Process)

Strategic Challenges

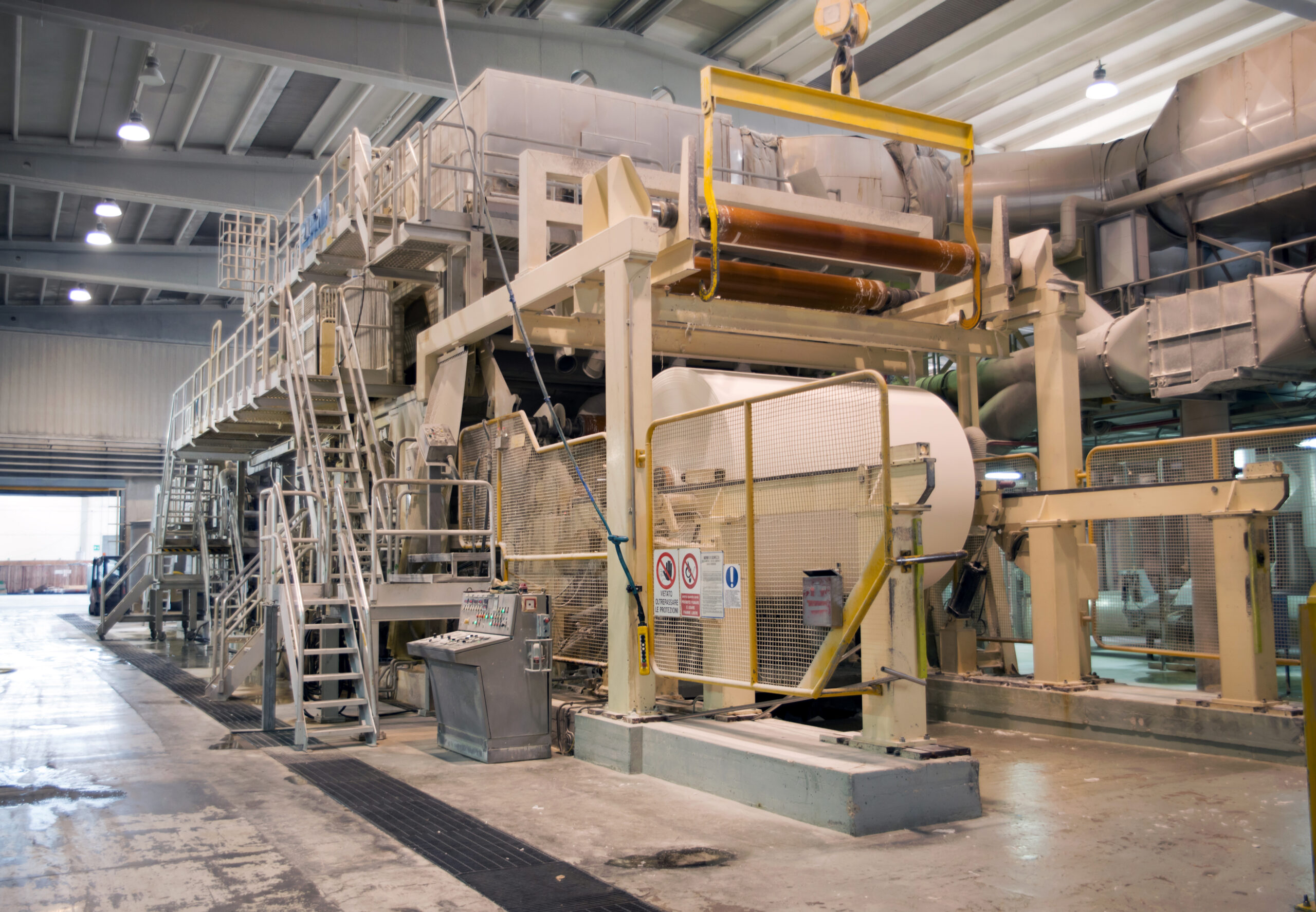

Production Reliability for

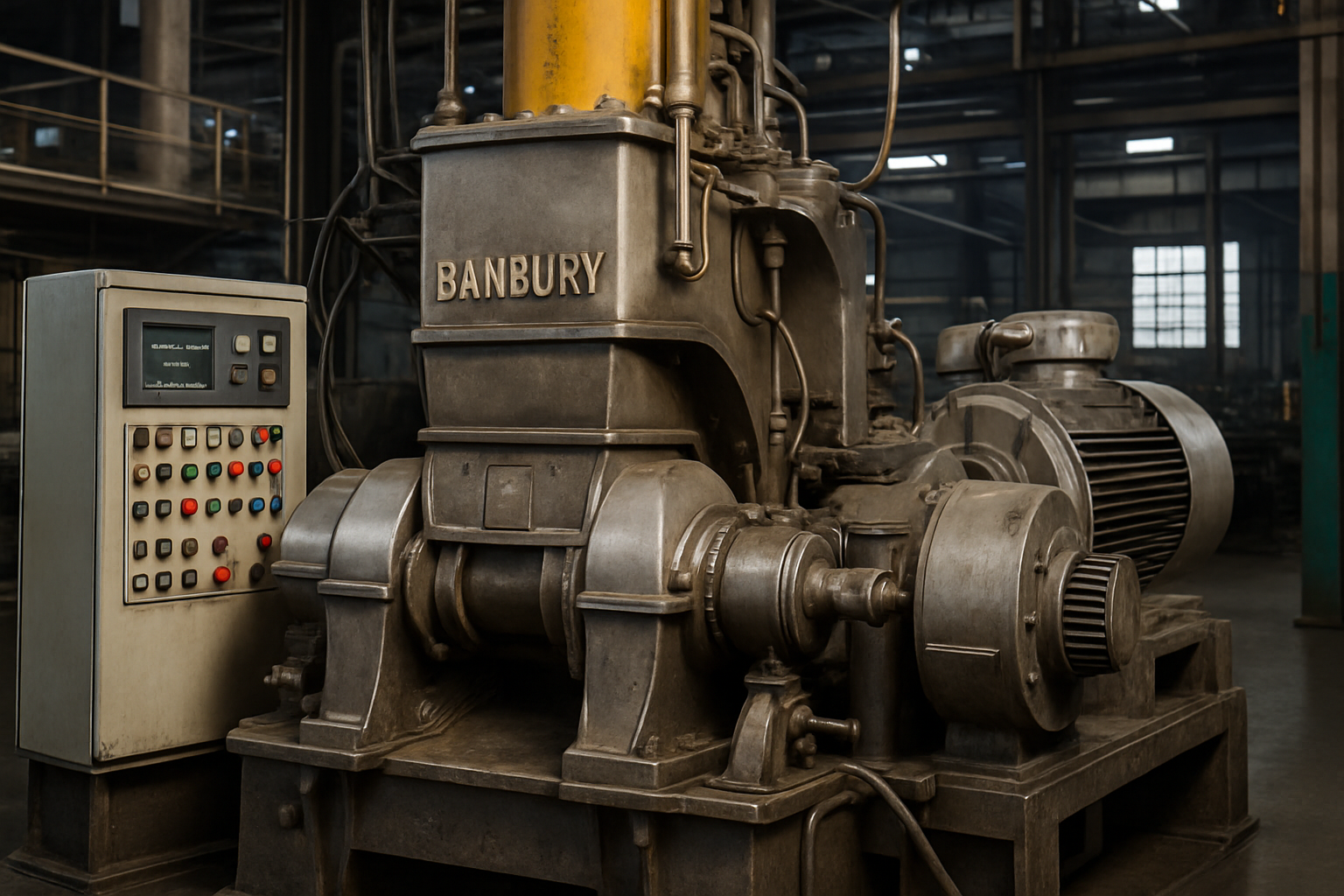

Tire & Rubber Industry

Tire industry = zero-defect, high-energy, volatile supply chain

In tire manufacturing, every defect risks recalls, every outage risks millions

Prescriptive Maintenance & Energy Optimization with Proven ROI in 6–12 Months

Banbury Mixer

Master Mixer

TSS Screw

TSS Calender gearbox

Dust Collecting Blower

Milling Section

Hold Mill

Feed Mil

Cracker Mill

Extruder

Duplex Extruder

Triplex Extruder

Quadraplex Extruder

Cushion Feed Extruder

Pork chop Extruder

Belt Extruder

Bead Construction

Bead Apex Extruder

Thread Applicator

Strip Winding Extruder

Inner Liner Calendering

Inner liner extruder

Inner Liner Roll

Fabric Cord Calendering

Pork chop Extruder

Calendar Hold Mill

Calendar Feed Mill

Calendar Rolls (4 roll section)

Cushion Calendar

Steel Belt Calendering

Steel Belt Cutting

Fabric Ply Cutting

Tyre Building

Curing & Inspection

heat and pressure, where unexpected failures can halt lines, cause costly rejects,

and disrupt tight delivery schedules. Energy-intensive curing and mixing processes

drive high power consumption, making inefficiencies costly.

Outcomes Delivered

Hours Eliminated

The PlantOS™ Difference

Tires

Rotating shafts and rollers

Strategic Challenges

Production Reliability for

Food & Beverages Industry

every stoppage risks compliance and waste

Prescriptive Maintenance & Energy Optimization with Proven ROI in 6–12 Months

Outcomes Delivered

Hours Eliminated

The PlantOS™ Difference

Strategic Challenges

Production Reliability for

Pharma & Personal Care Industry

Prescriptive Maintenance & Energy Optimization with Proven ROI in 6–12 Months

Outcomes Delivered

Hours Eliminated

The PlantOS™ Difference