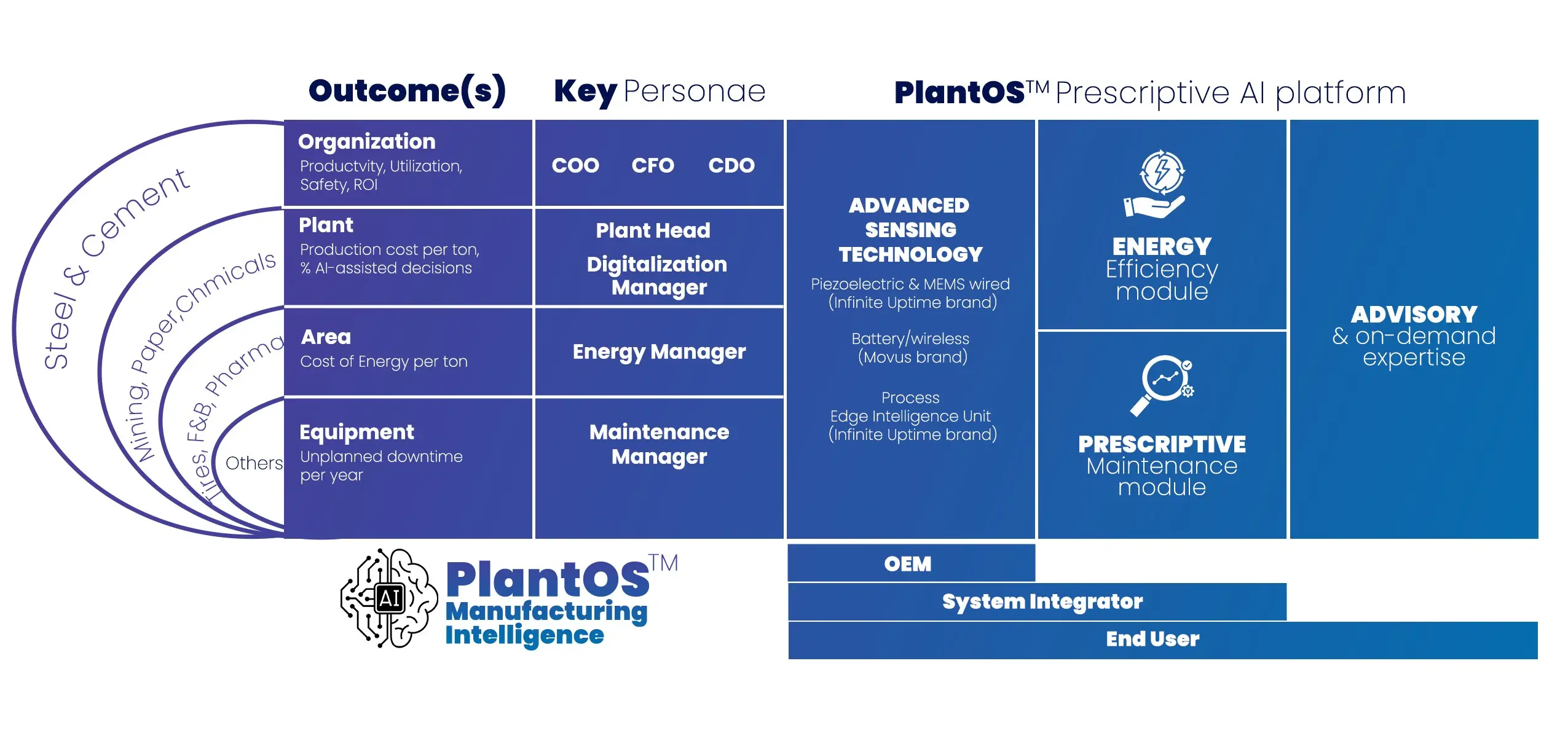

PlantOS™ is a layered intelligence ecosystem,

where advanced sensing meets vertical AI and on-demand expertise.

- Advanced Sensing Technology (MEMS & Piezoelectric sensors) gathering precision data

- Collaborative, industry-specific Prescriptive AI that learns from every equipment it monitors

- On-demand human intelligence to close expertise gaps instantly

Advanced

Sensing Technology

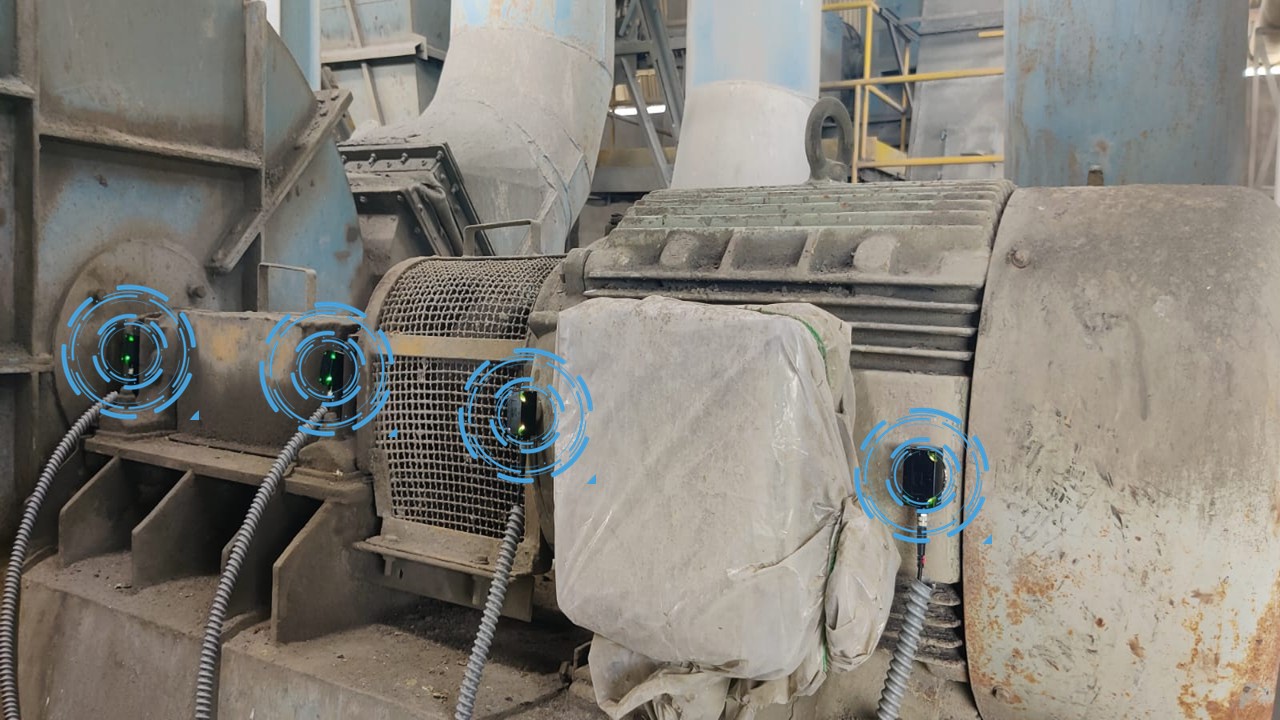

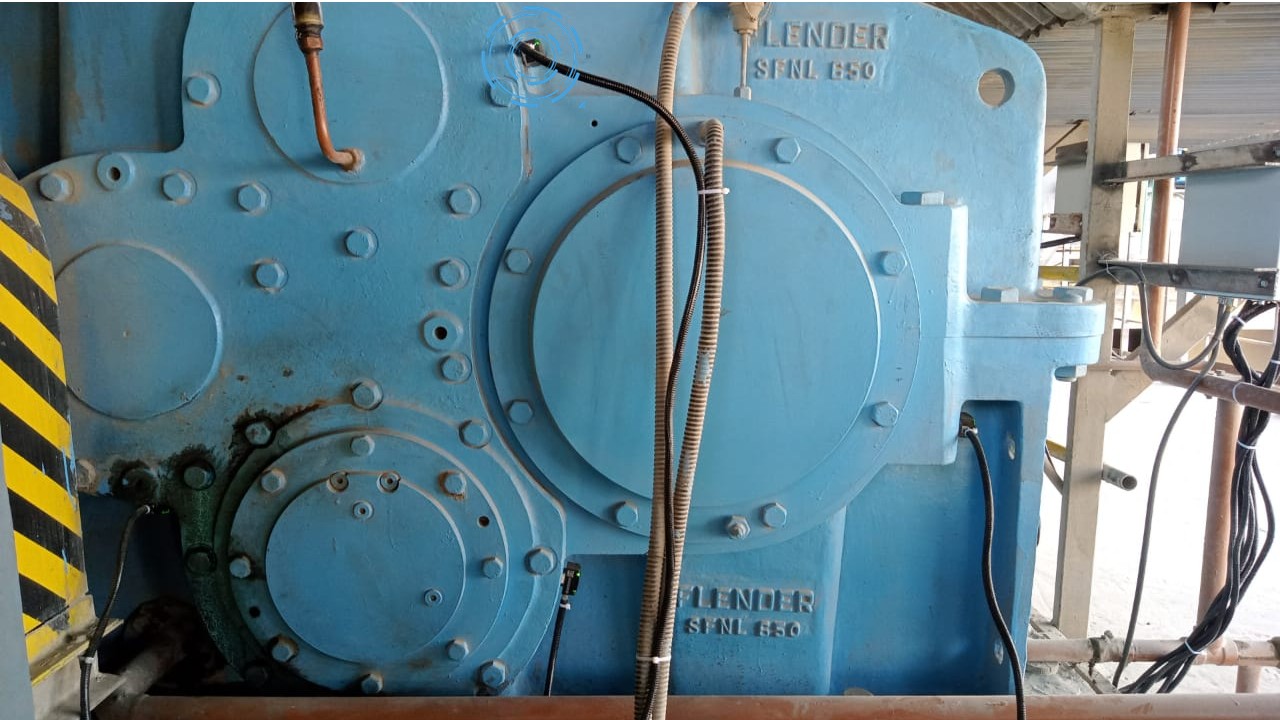

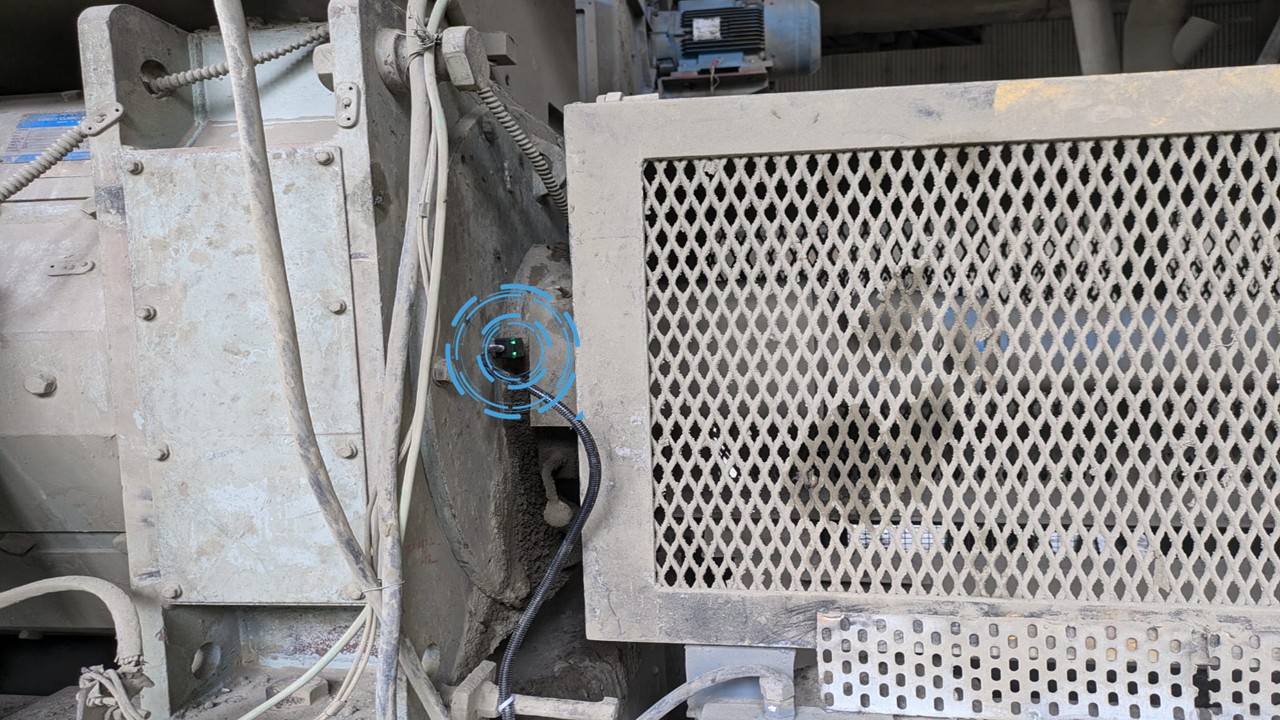

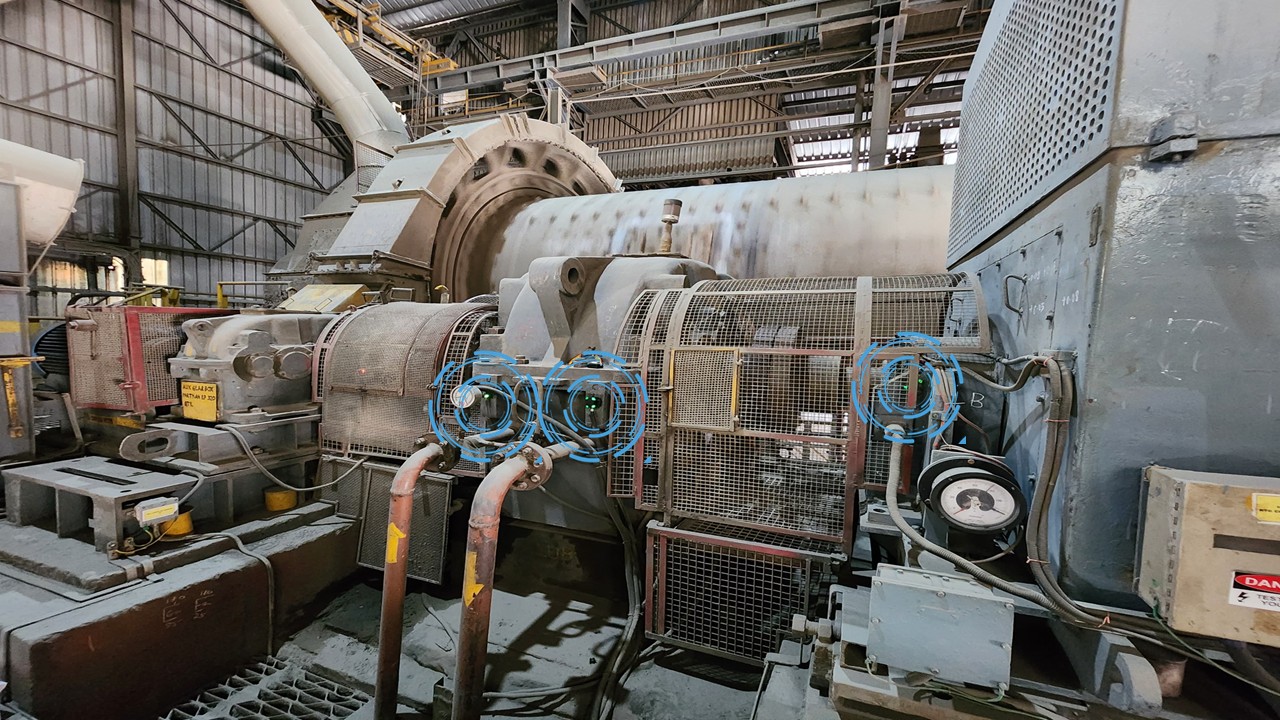

PlantOS™ comes alive with advanced sensing technology, engineered to capture granular data in the harshest industrial environments. Our sensors don't just survive in extremes they thrive.

High surface temperature

up to 150°C

Ultra low-speed

rotations

as low as 2 RPM

Acidic

& corrosive environment zones

High Humidity environment

Explosive environment

Underwater environment (IP68 certified*)

Advanced Sensing Technology

Engineered to Endure, Designed to Deliver

Sensors That Withstand Every Industrial Environment

vEdge 3XTURPM

Wired MEMS Technology

Features

- •

Contact temperature range (with vibration pad mounting) -20°C to 85°C - •

Equipment with transient load patterns, operating between Revolution Per Minute (RPM) of 20 RPM to 5000 RPM such as

- Blowers

- Compressors

- Mills

- Pumps

- Gearboxes

Thank you for your interest in

PlantOS™ Prescriptive AI.

Enter your official work email to unlock specs delivering

3 outcomes in 1 prescription — zero guesswork.

vSense 3XT

Wired Piezo-electric Technology

- • Asset contact temperature range: -40° C to 120° C

- • Equipment with transient load patterns, operating between Revolution Per Minute (RPM) of 100 RPM to 3900 RPM such as

- Steam Fans

- Corrosive Environment Pumps (SAP/PAP)

- Ventilation Fans

- High Speed Motors

- High Speed Compressors

Thank you for your interest in

PlantOS™ Prescriptive AI.

Enter your official work email to unlock specs delivering

3 outcomes in 1 prescription — zero guesswork.

vSense 1XT

Wired Piezo-electric Technology

- • Asset contact temperature range: -40° C to 130° C

- • Equipment with transient load patterns, operating between Revolution Per Minute (RPM)* of 2 RPM to 3900 RPM such as

- Blowers

- Compressors

- Mills

- Pumps

- Gearboxes

Thank you for your interest in

PlantOS™ Prescriptive AI.

Enter your official work email to unlock specs delivering

3 outcomes in 1 prescription — zero guesswork.

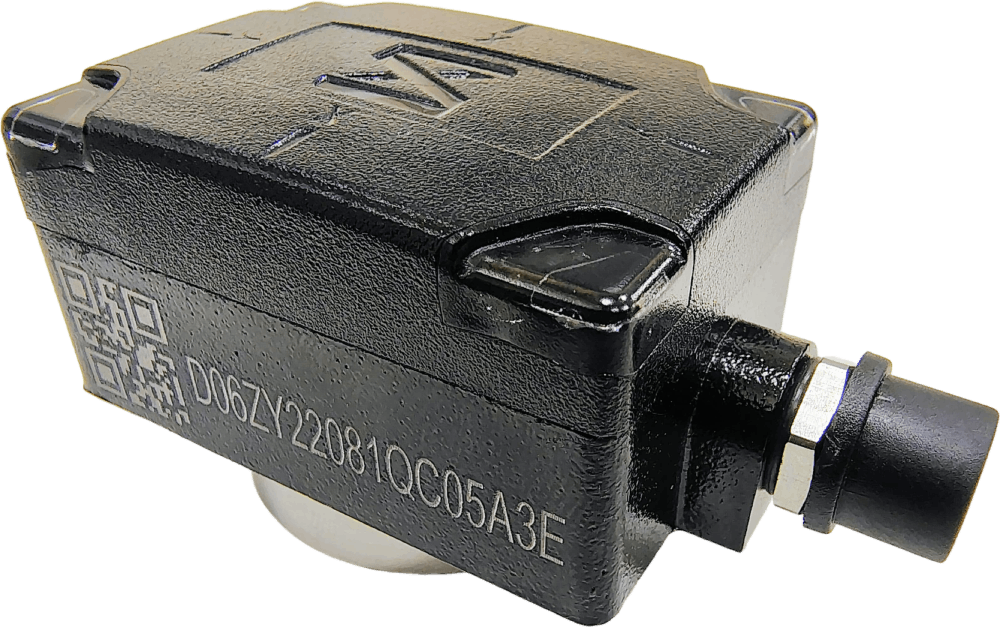

vSense 3XTRPM

Wired Piezo-electric Technology

- • All-in-One Monitoring Unit – Combines 3-axis vibration, temperature, and RPM sensing in one compact module.

- • Compact & Light weight

- • Asset contact temperature range: -20° C to 120° C

- • Equipment with transient load patterns, operating between Revolution Per Minute (RPM) of 20 RPM to 12000 RPM such as

- Steam Fans

- Corrosive Environment Pumps (SAP/PAP)

- Ventilation Fans

- High Speed Motors

- High Speed Compressors

Thank you for your interest in

PlantOS™ Prescriptive AI.

FitMachine 3XT

Wireless MEMS Technology

- • Contact surface temperature range: -20° C to 80° C

- • Battery Life ≥ 2 years – varies with duty cycle

- • Equipment with transient load patterns, operating between Revolution Per Minute (RPM) of 100 RPM to 3600 RPM such as

- Blowers

- Pumps

- Gearboxes

Thank you for your interest in

PlantOS™ Prescriptive AI.

Enter your official work email to unlock specs delivering

3 outcomes in 1 prescription — zero guesswork.

FitMachine 3XT Ex

Wireless MEMS Technology

- • Asset contact temperature range: -25° C to 75° C

- • ATEX certified – suitable for explosive environments

- • Battery Life ≥ 5 years – varies with duty cycle

- • Equipment with transient load patterns, operating between Revolution Per Minute (RPM) of 20 RPM to 5000 RPM such as

- Blowers

- Pumps

- Gearboxes

Thank you for your interest in

PlantOS™ Prescriptive AI.

Enter your official work email to unlock specs delivering

3 outcomes in 1 prescription — zero guesswork.

EDGEIU

process parameters—including temperature, pressure, and energy—and securely transmits this

data to the collaborative AI within the PlantOS™ ecosystem for advanced analysis and optimization.

EDGEIU–Touch—each designed to integrate seamlessly into distinct process control architectures.

EDGEIU-PLC

Purpose-built for direct integration with Programmable Logic Controllers. It ensures rapid data collection from machine-level control systems, enabling real-time visibility and performance insights.

Thank you for your interest in

PlantOS™ Prescriptive AI.

Enter your official work email to unlock specs delivering

3 outcomes in 1 prescription — zero guesswork.

EDGEIU-DCS

Tailored for complex Distributed Control Systems, it consolidates data from multiple process loops and control layers, ensuring cohesive monitoring and coordinated process optimization across the plant.

Thank you for your interest in

PlantOS™ Prescriptive AI.

Enter your official work email to unlock specs delivering

3 outcomes in 1 prescription — zero guesswork.

EDGEIU-Touch

A versatile interface unit that combines local data visualization with intelligent connectivity, offering operators on-the-ground process monitoring and secure collaboration with the central PlantOS™ AI platform.

Thank you for your interest in

PlantOS™ Prescriptive AI.

Enter your official work email to unlock specs delivering

3 outcomes in 1 prescription — zero guesswork.

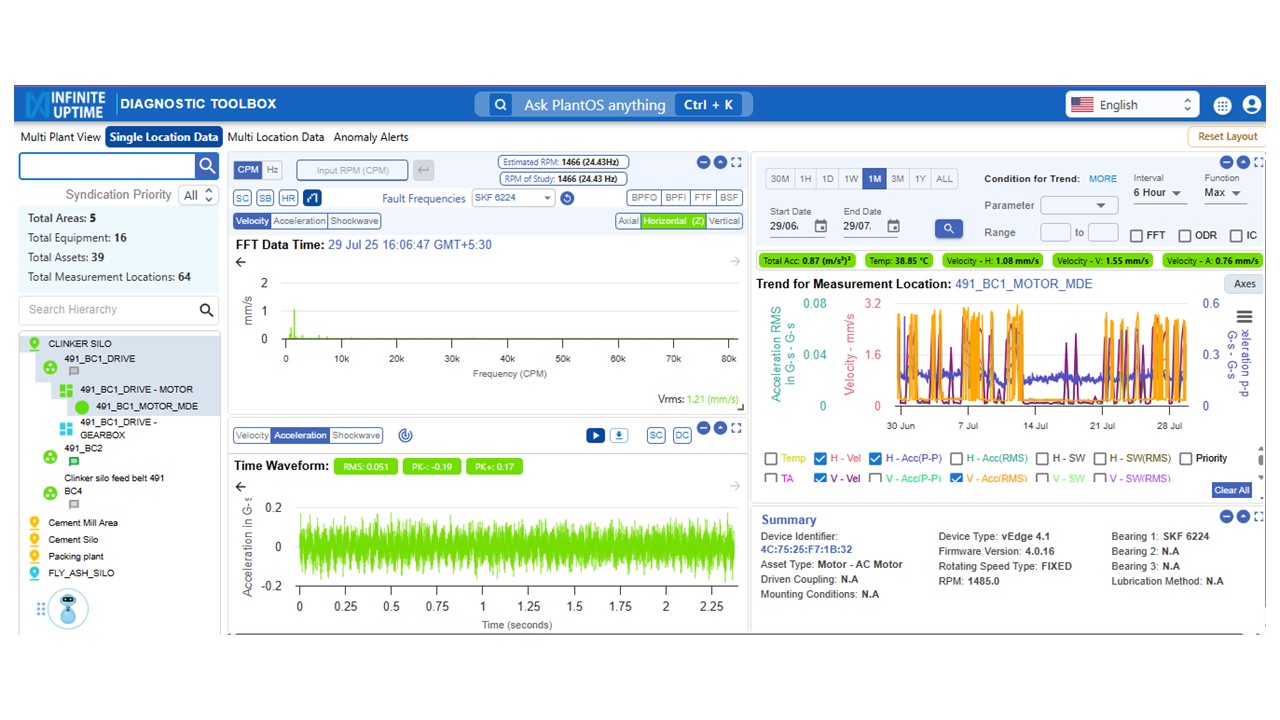

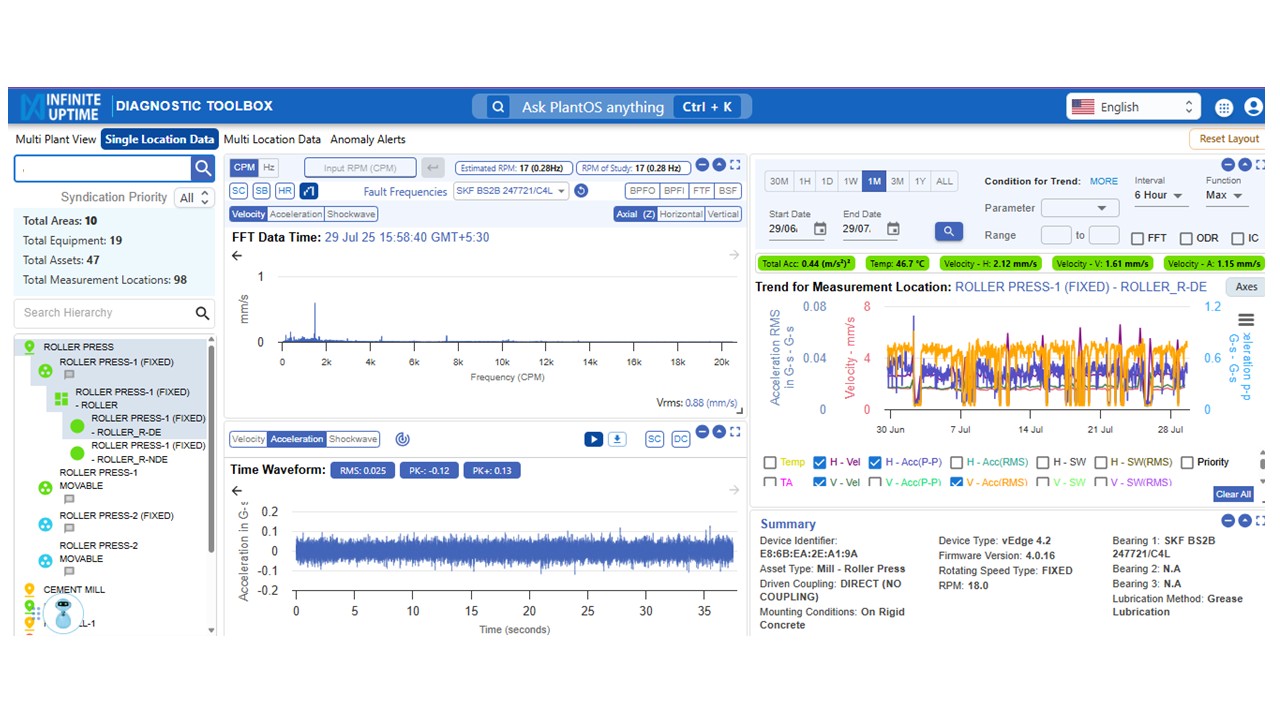

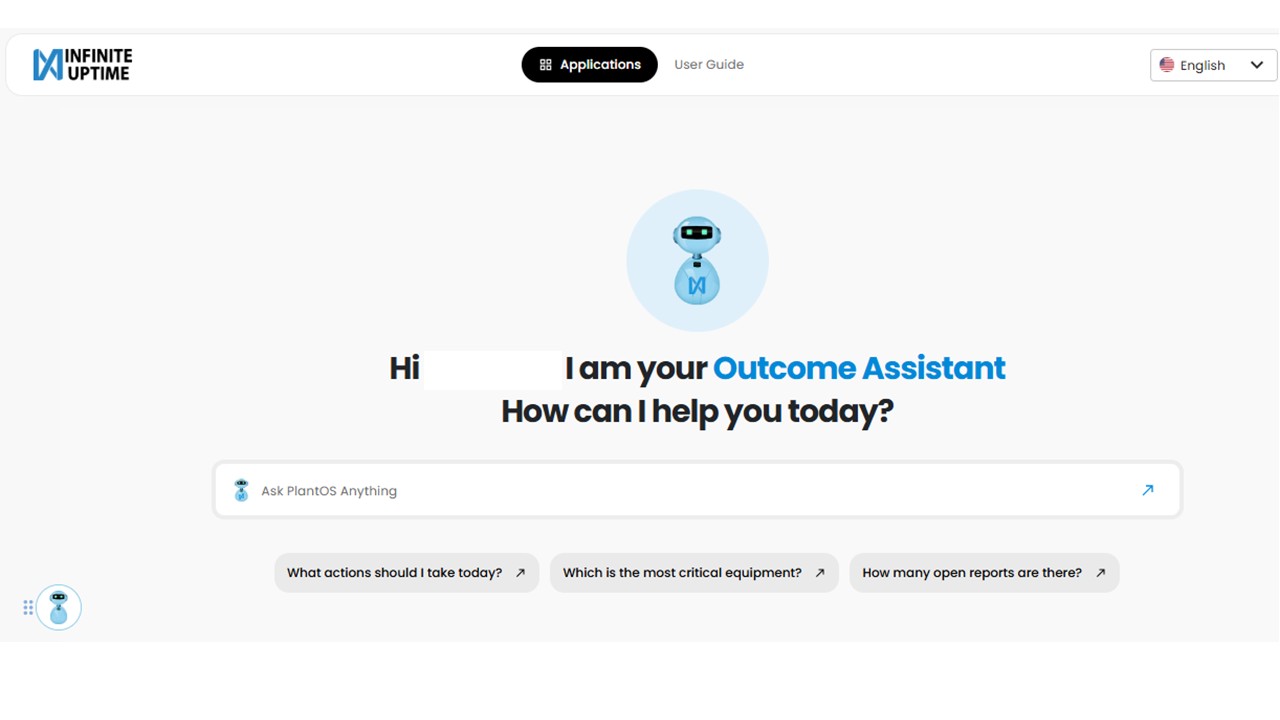

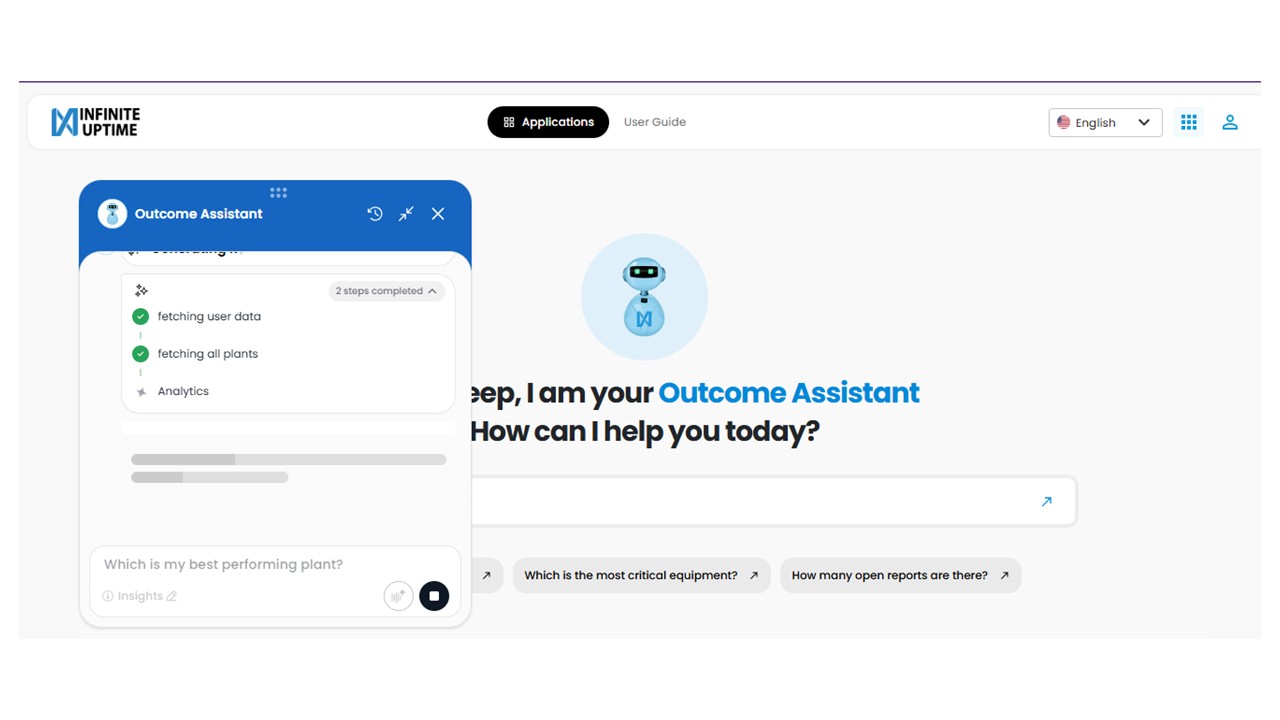

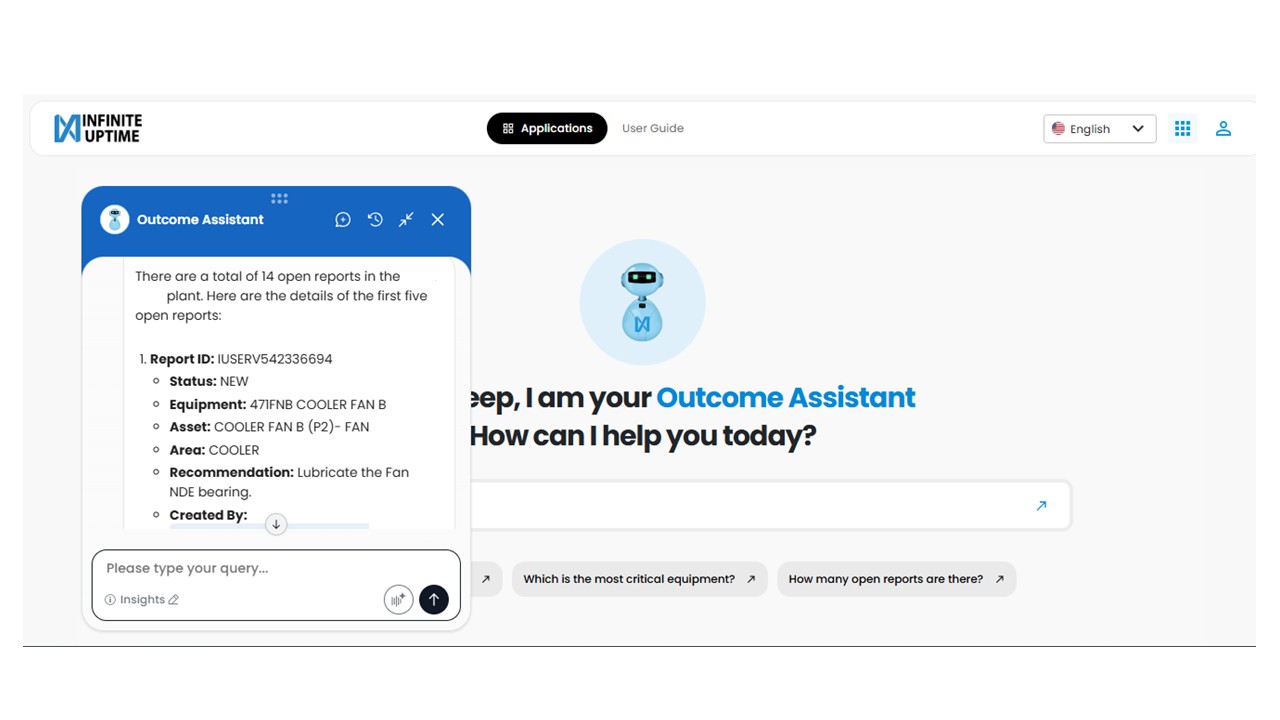

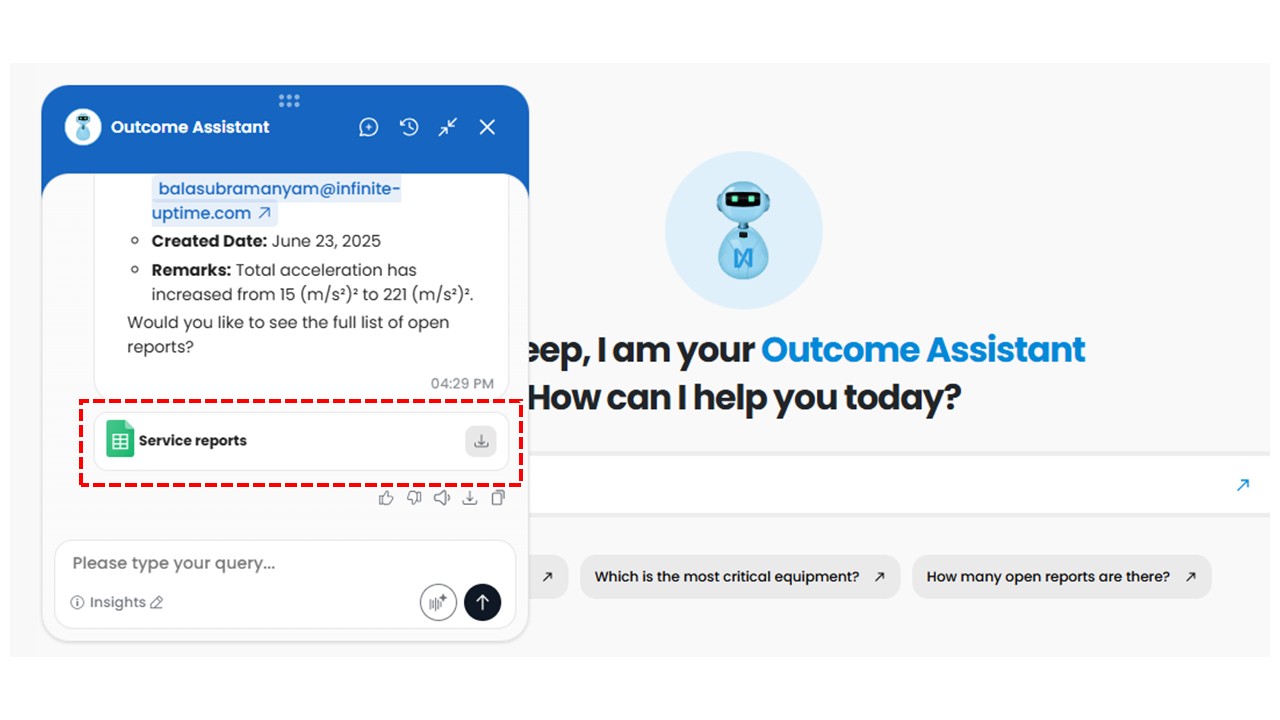

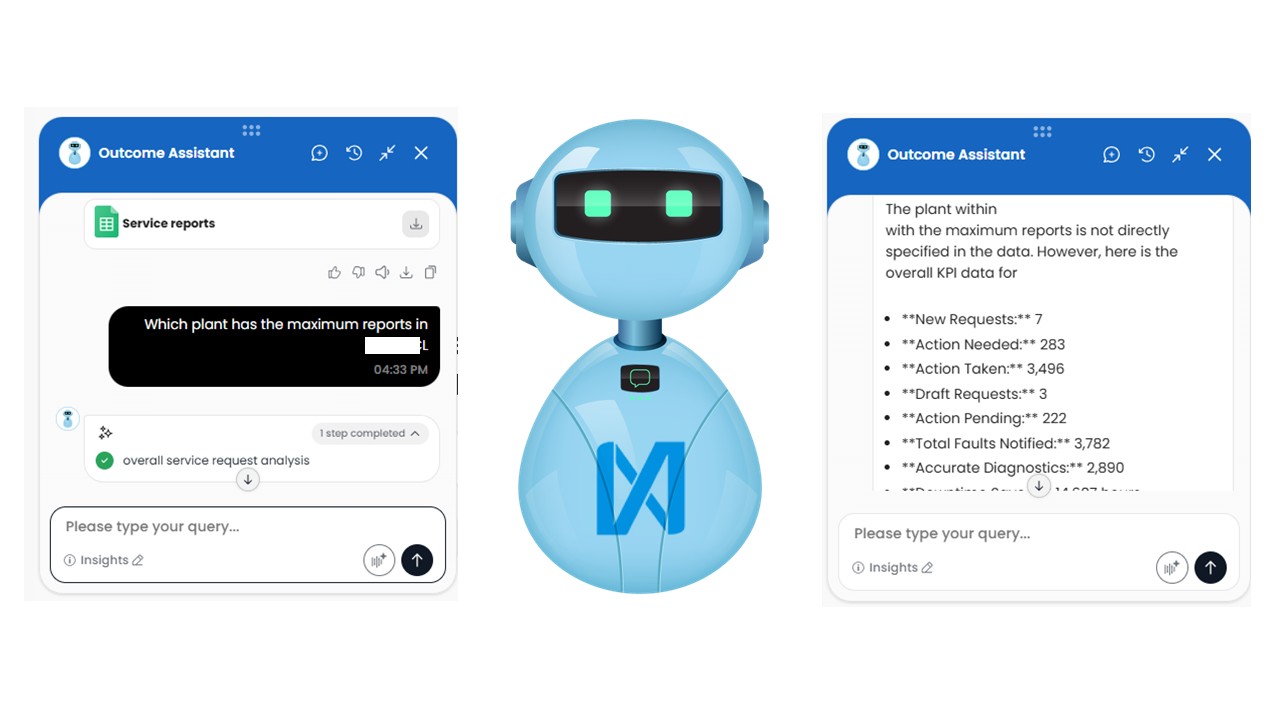

Collaborative AI

Your Outcome Assistant

- Trained on 80,000+ measurement locations (and growing!)

- Optimized across Steel, Cement, Aluminium, Chemicals, Tires, Pharma, F&B, and more

- Achieves 99.97% prediction accuracy

This is not just an algorithm — this is your extended plant intelligence.

From predicting bearing failures, to prescribing cost-saving maintenance activities, to alerting energy managers on KPI drifts, the Outcome Assistant translates data into direct actions that protect ROI, eliminate downtime, and safeguard workforce safety.

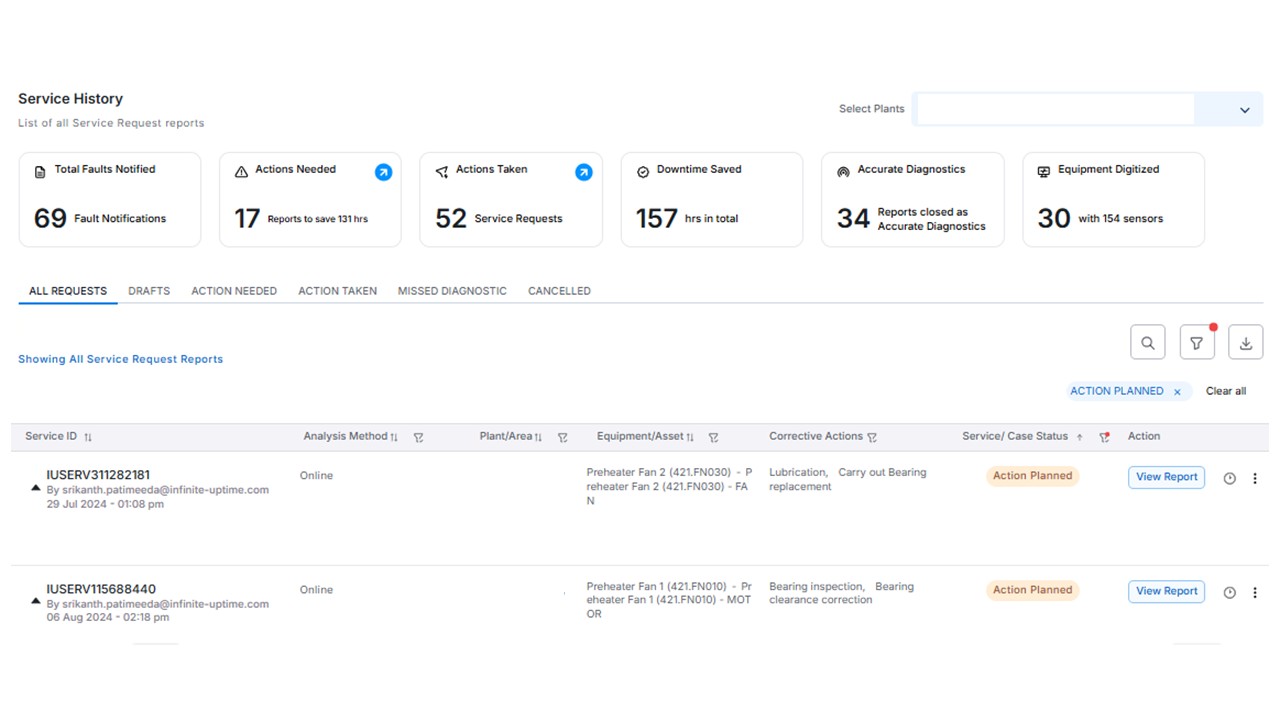

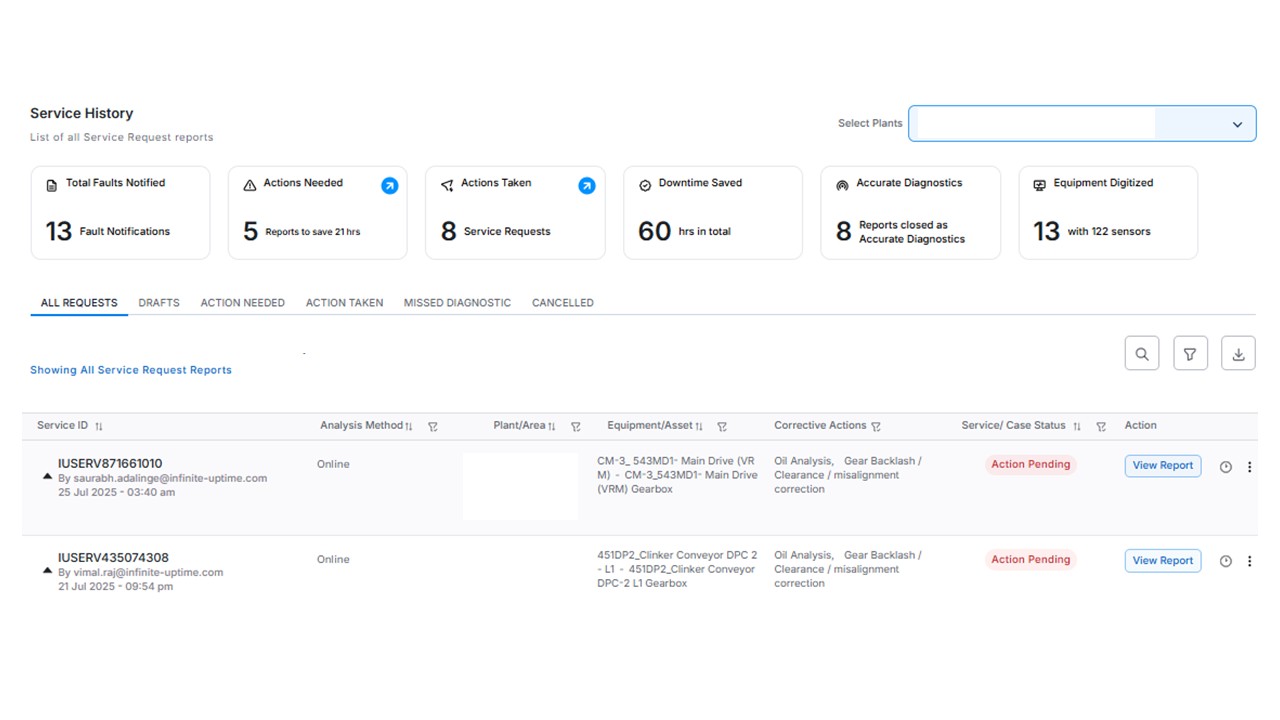

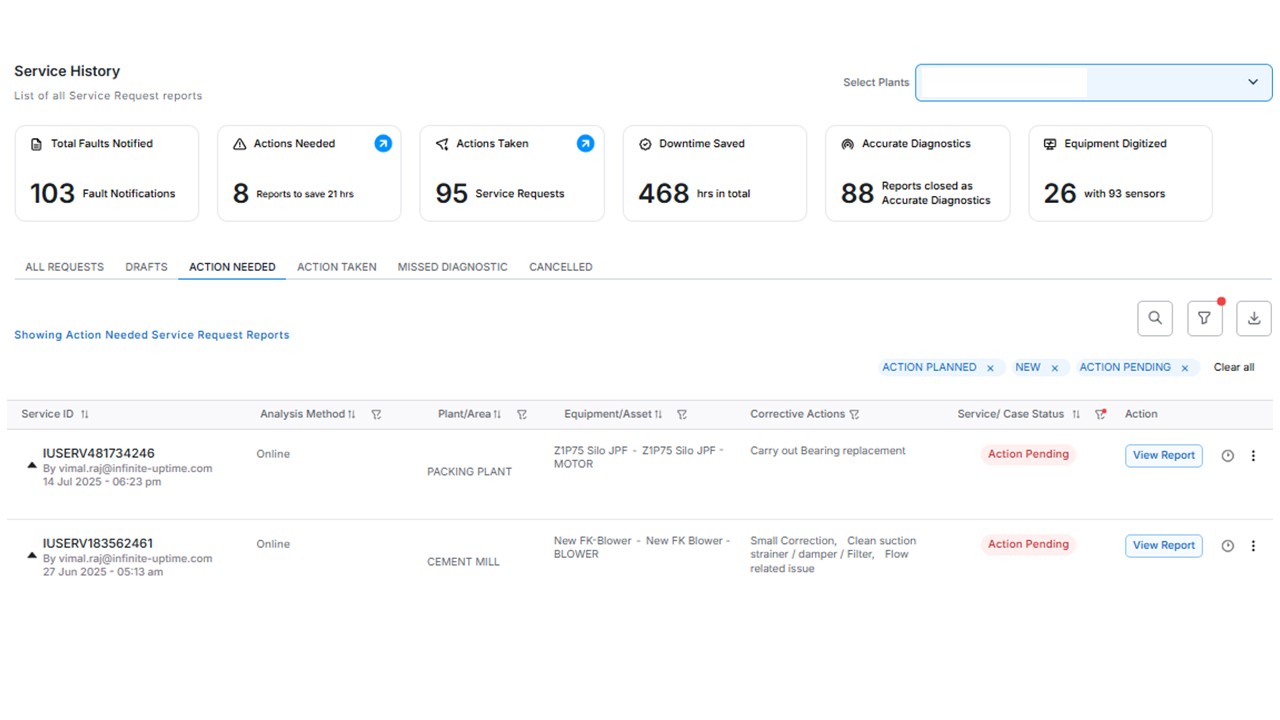

When Artificial Intelligence

Meets Human Ingenuity

With PlantOS™, intelligence is layered — and

human expertise is the final seal of trust.

24 × 7 Remote Monitoring by specialists

On-demand domain expertise available anytime, anywhere

Centre of Excellence ensuring every review, every report, every anomaly is addressed and closed with precision

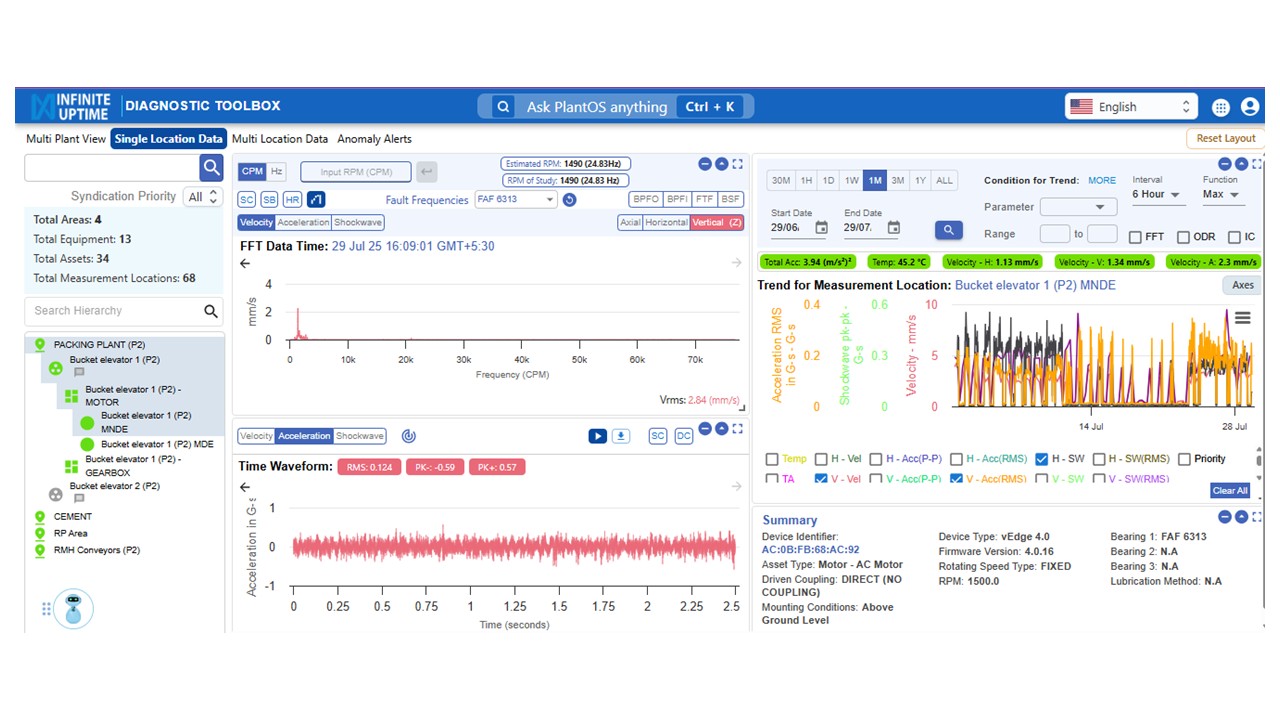

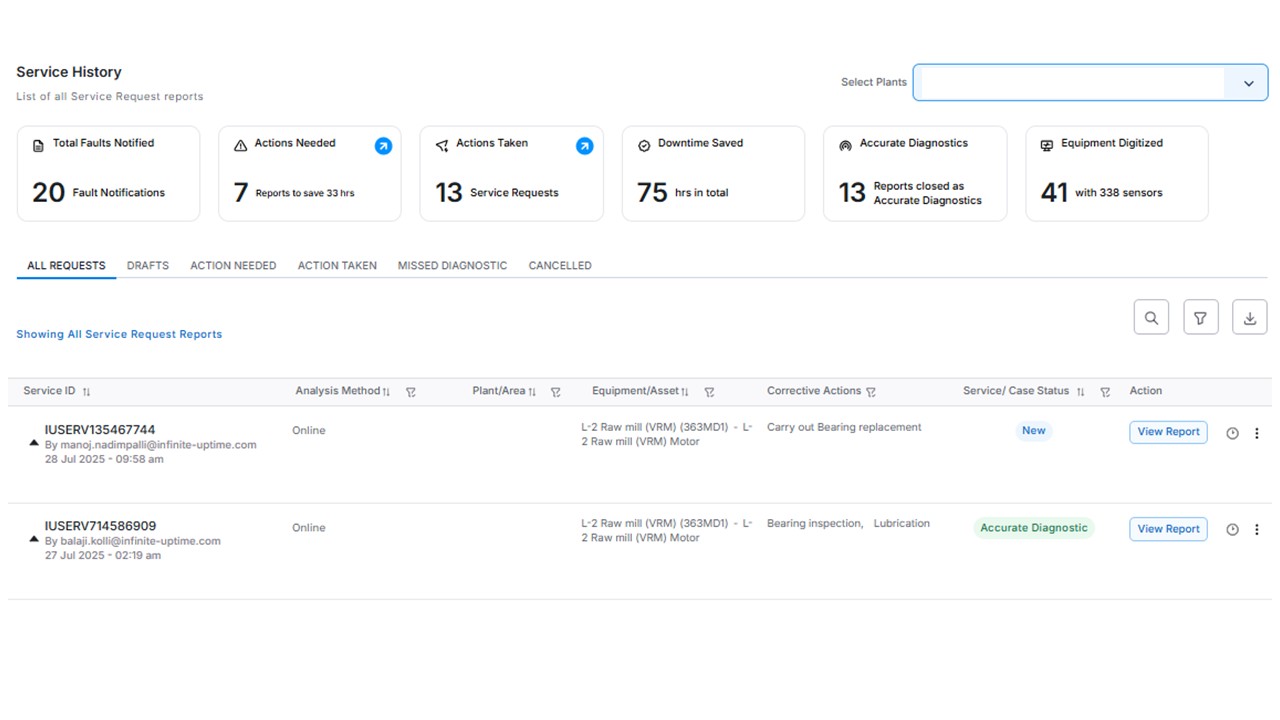

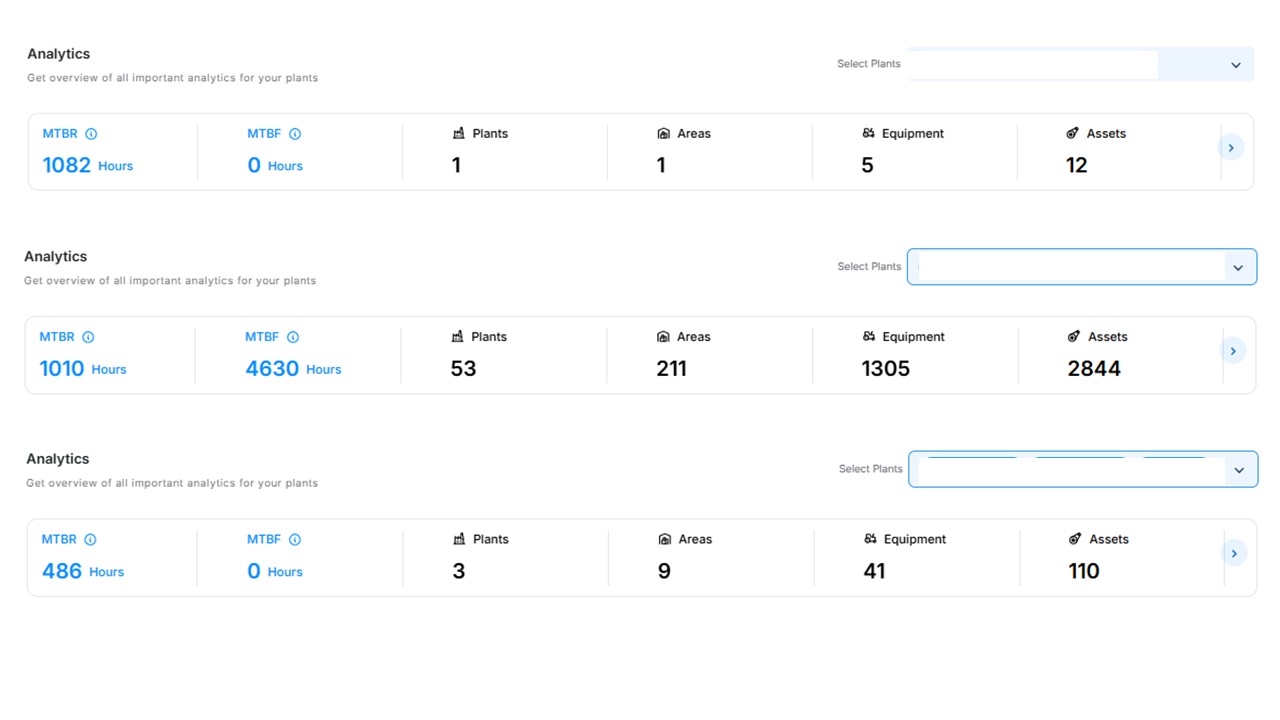

Live Action

PlantOS™ Live in Action

Prescriptive Maintenance

Energy Efficiency

Prescriptive Maintenance

Prescriptive Maintenance