Energy Efficiency

It empowers decision-making with data-driven insights that boost reliability and efficiency.

What is Energy Efficiency by PlantOS™?

Energy Efficiency, or Energy Optimization, is the strategic process of maximizing output while minimizing energy consumption, cost, and environmental impact across key manufacturing processes.

PlantOS™ deliver Energy Efficiency

How Does PlantOS™ deliver Energy Efficiency

(Energy Optimization) for your plant?

PlantOS™ delivers Energy Efficiency (Energy Optimization) through five functional

modules—designed to baseline, benchmark, optimize, collaborate, and prescribe

actionable interventions for your critical manufacturing processes.

Sense

& Ingest

Enables real-time collection and ingestion of energy consumption data at the equipment and plant level, providing a foundation for precise energy monitoring and optimization.

Administer &

Configure

Configures parameters for energy usage, ensuring proper monitoring of limits, and notifications to support efficient energy management.

Diagnose &

Analyze

Uses analytics and AI to detect abnormal energy consumption patterns or inefficiencies and identifies root causes for excessive energy use.

Act

& Resolve

Empowers teams with actionable insights to implement targeted interventions that reduce energy waste and optimize equipment efficiency.

Collaborate &

Integrate

Facilitates integration of energy data across departments and third-party systems, enabling collaborative initiatives and automated responses for holistic energy optimization.

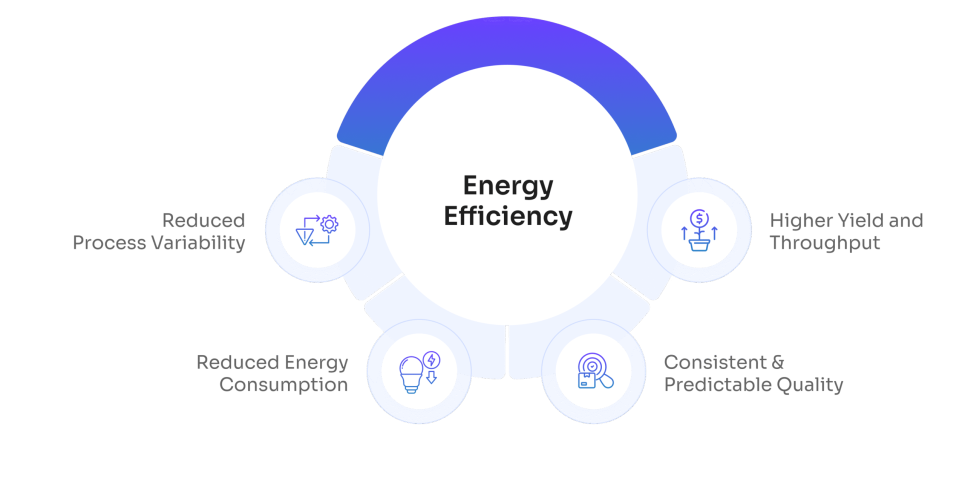

Production Outcomes

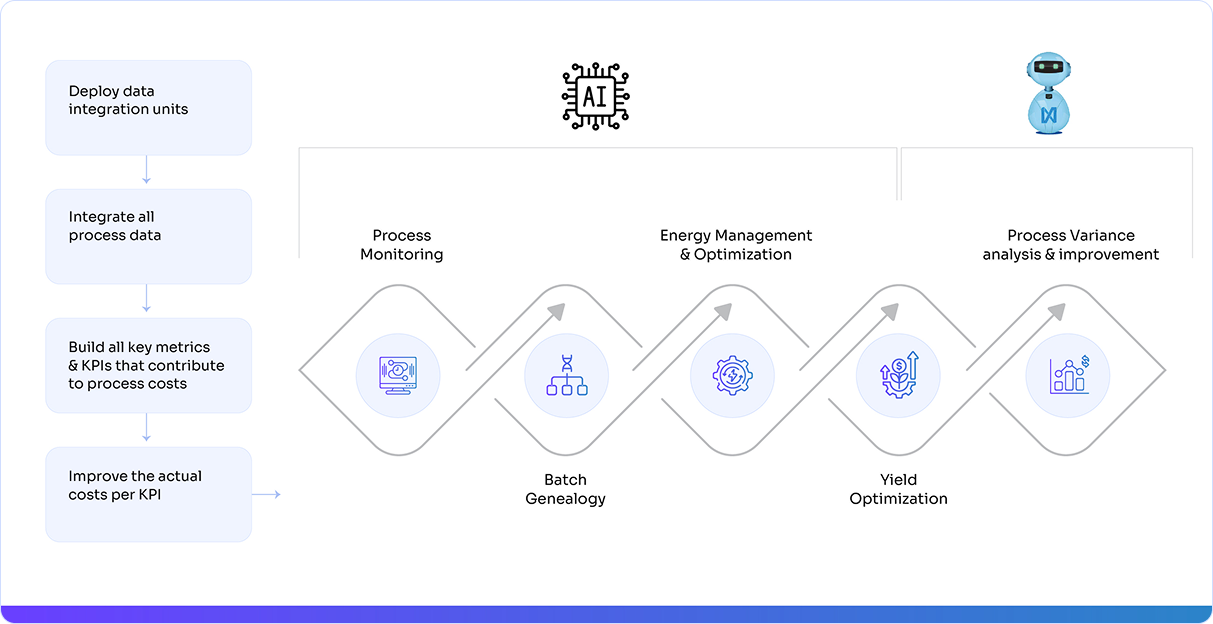

What is the Path to Achieve Production Outcomes through Energy Efficiency?

With PlantOSTM’s Energy Efficiency (Energy Optimization) solution, manufacturers gain a clear, real-time view of their plant’s energy and process baseline. This visibility creates the foundation to benchmark performance, identify optimization opportunities, and sustain long-term efficiency gains.

The Infinite Uptime

Energy Efficiency Framework

you on the path to achieving superior energy efficiency.

Process Monitoring:

Batch Genealogy:

Tracing and recording the production history of each batch for quality assurance, traceability, and regulatory compliance.